Volkswagen Golf Service & Repair Manual: Tools and materials commercially available

Caution

Caution

| Non-authorised tools or materials (e.g. leak

inhibitor additive) may cause damage or adversely

influence the system. |

| Only tools and materials approved by the

manufacturer may be used. |

| The use of non-approved tools or materials will

render the warranty void. |

|

|

|

|

|

Overview |

page |

| Fin comb |

→ Fig. |

| Charging hoses 5/8"-18

UNF with valve opener |

→ Fig. |

| Connector piece for

pressure bottles for refrigerant and sealing ring with quick-release

coupling or threaded connector 5/8"-18 UNF |

→ Fig. |

| Valve caps 5/8" -18 UNF |

→ Fig. |

| Manifold gauge with

pressure limiter for nitrogen |

→ Fig. |

| Quick-release coupling

adapter for service connections, 2 included in items supplied with air

conditioner service station |

→ Fig. |

| Open ring spanners of

widths matching those of the threaded connections on the refrigerant

pipes. |

not illustrated |

| Valve opener for charging

hoses |

not illustrated |

| Connection nipple for

tapered seal 5/8"-18 UNF |

not illustrated |

| Compressed air gun with

rubber nozzle |

not illustrated |

| Hand shut-off valve 5/8"

- 18 UNF |

not illustrated |

| Recycling bottle for

refrigerant R134a |

not illustrated |

| Digital thermometer |

not illustrated |

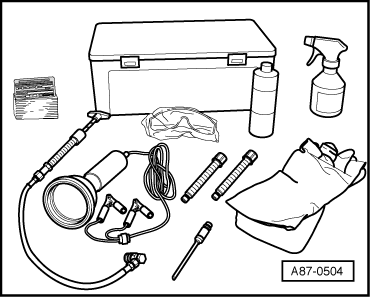

| Protective gloves |

not illustrated |

| Protective goggles |

not illustrated |

| Refrigerant R134a with

pressure bottle (contents as required) |

not illustrated |

| Nitrogen in pressure

bottle |

not illustrated |

| Strap wrench (oil filter) as

counterhold for poly V-belt pulley |

not illustrated |

|

Overview |

page |

| Charging hose with connector to

the workshop's compressed air system |

→ Fig. |

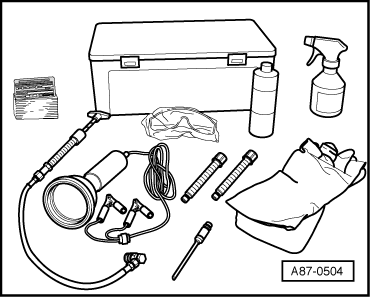

| Tools and materials available from

distribution centre or importer |

Caution

Caution

| Non-authorised tools or materials (e.g. leak

inhibitor additive) may cause damage or adversely

influence the system. |

| Only tools and materials approved by the

manufacturer may be used. |

| The use of non-approved tools or materials will

render the warranty void. |

|

|

|

|

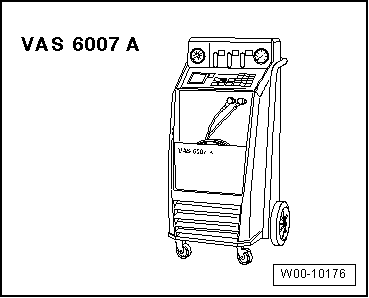

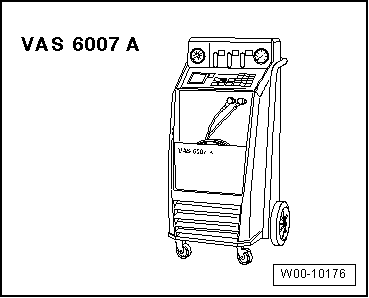

| Air conditioning service station -VAS 6007A- (and further

service stations currently available) |

| The procedures for testing, extracting (recycling),

evacuating and charging should be carried out in accordance with

the respective user's manual. |

| The installed filter and dryer must be renewed at the latest

at the end of the period of use specified in the operating

instructions and every time that the station is emptied (keep

replacement filter on hand. they can be ordered from the

manufacturer of the device, see user's manual. |

| Air conditioner service stations or purging devices approved

by VW but not shown here may also be used. |

Note Note

| This air conditioner service station incorporates the

following common individual devices: charging cylinder, manifold

gauge, vacuum pump, shut-off valves and charging hoses. |

| This air conditioner service station includes one of each

type of quick-release coupling (for high-pressure and

low-pressure side service connections). |

|

|

|

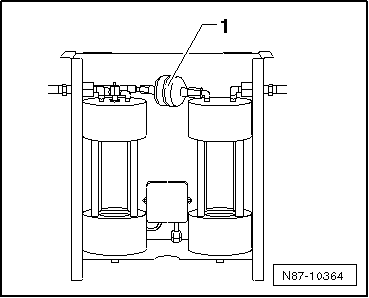

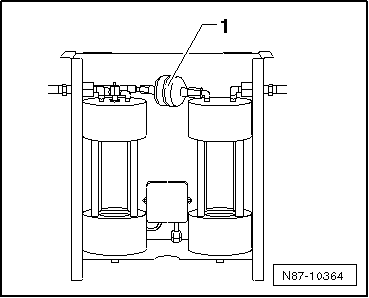

| Purging device for refrigerant circuits -VAS 6337/1- from

“Behr” or later model. |

Note Note

| With filter -1- and two large

cylindrical sight glasses |

| The filter in the purging device for refrigerant circuits

should be changed after about 2 purging cycles (depending on the

level of contamination from the purged refrigerant circuits). If

a heavily contaminated refrigerant circuit is purged (the

refrigerant oil from the refrigerant circuit is black and

viscous or there are large amounts of shavings in the

refrigerant circuit) renew filter after purging refrigerant

circuit. |

|

|

|

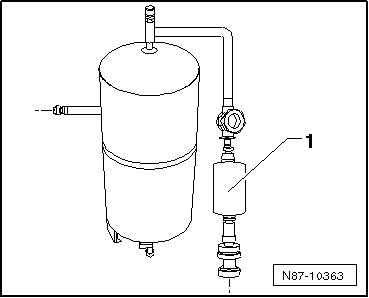

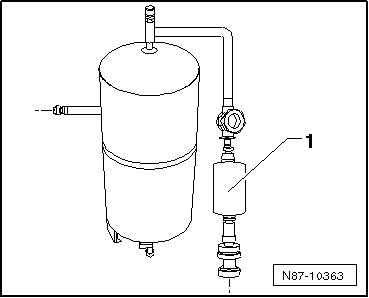

| Purging device for refrigerant circuits -VAS 6336/1- from

“Waeco” or later model. |

Note Note

| With filter -1- and one sight

glass |

| The filter in the purging device for refrigerant circuits

should be changed after about 2 purging cycles (depending on the

level of contamination from the purged refrigerant circuits). If

a heavily contaminated refrigerant circuit is purged (the

refrigerant oil from the refrigerant circuit is black and

viscous or there are large amounts of shavings in the

refrigerant circuit) renew filter after purging refrigerant

circuit. |

|

|

|

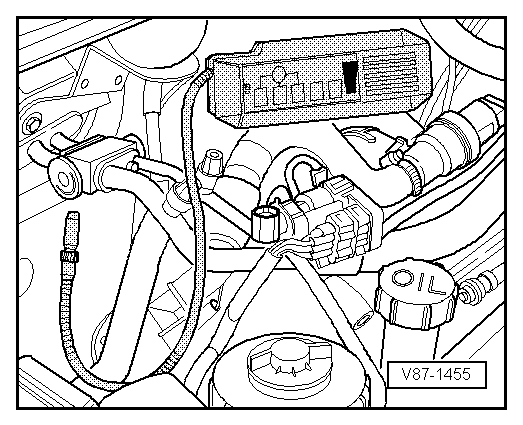

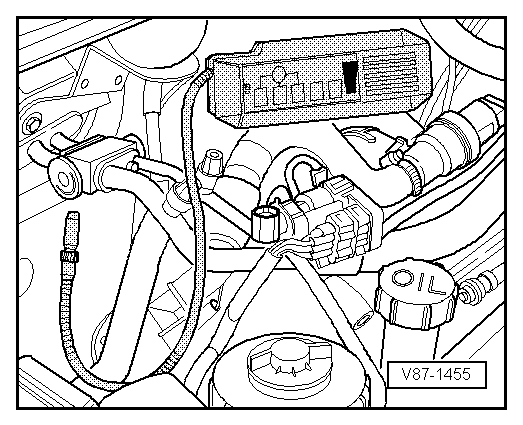

| Leak detector -V.A.G 1796- |

|

|

|

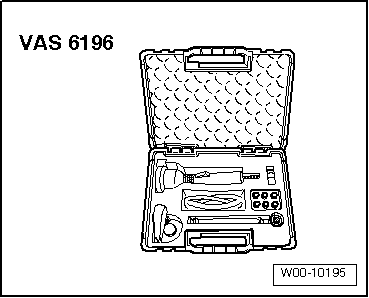

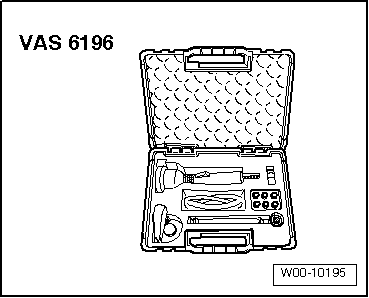

| Leak detecting system -VAS 6196- |

|

|

|

| Leak detecting system VAS 6201 or later model |

|

|

|

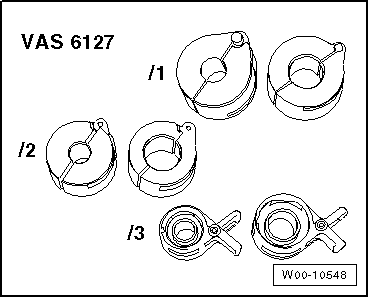

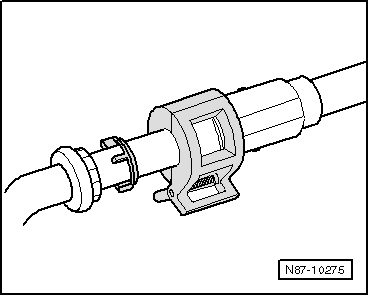

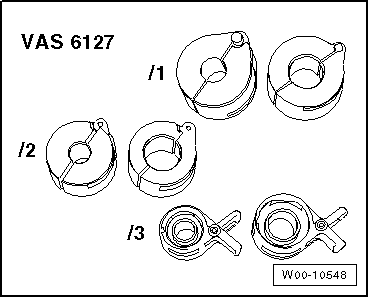

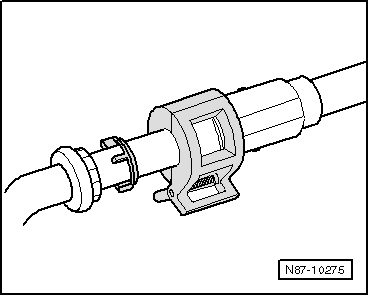

| Release tool -VAS 6127- case comprising release tool -VAS

6127/1-release tool -VAS 6127/2- and release tool -VAS 6127/3- |

|

|

|

| Release tool -VAS 6127/1-release tool -VAS 6127/2- |

|

|

|

| Release tool -VAS 6127/3- |

| Green NW 8 for high-pressure line |

| Black NW 13 for low-pressure line |

|

|

|

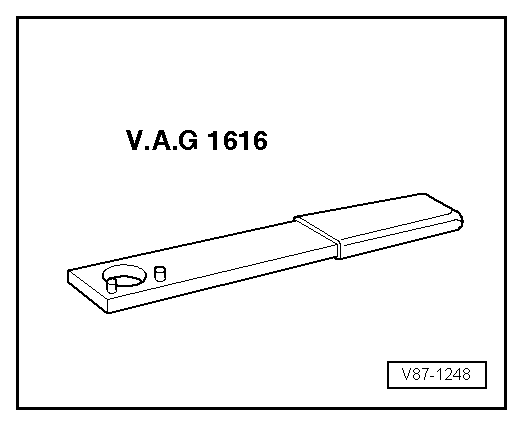

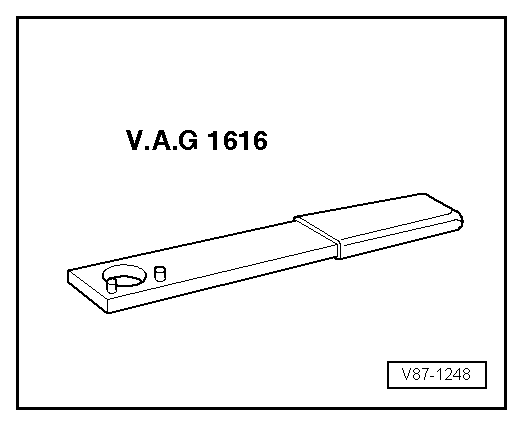

| Counterhold -V.A.G 1616- for clutch pulley (for “Sanden” air

conditioner compressors) |

|

|

|

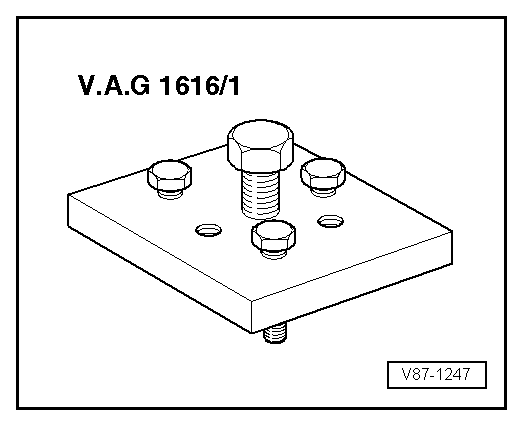

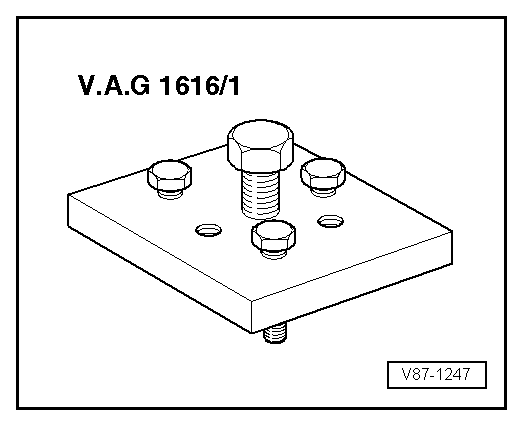

| Puller -V.A.G 1616/1- for clutch pulley (for “Sanden” air

conditioner compressors) |

|

|

|

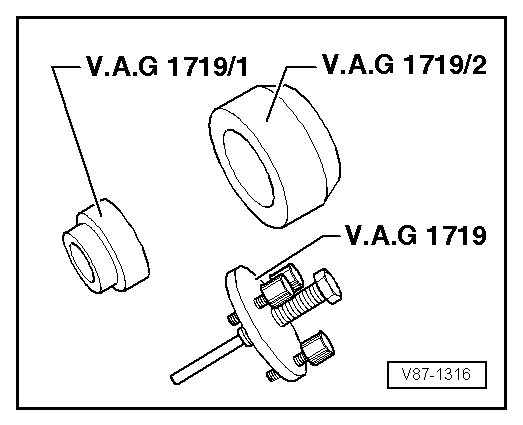

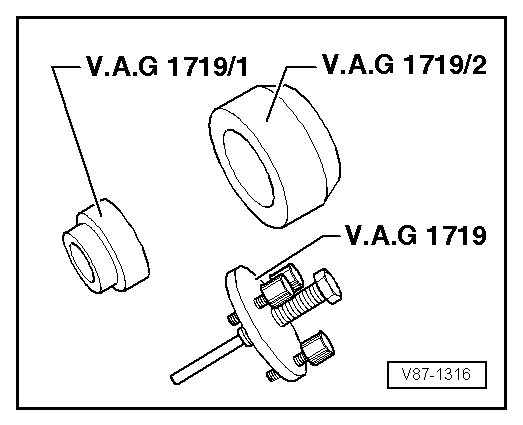

| Magnetic clutch puller -V.A.G 1719- (for “Zexel” air

conditioner compressors) |

|

|

|

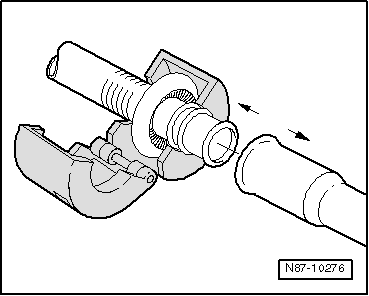

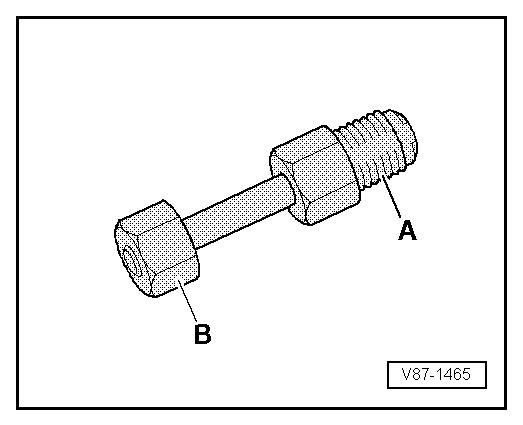

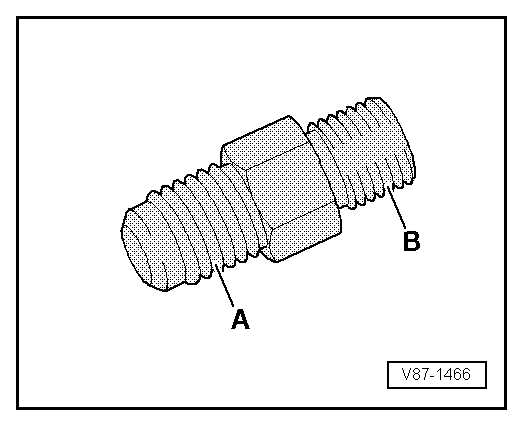

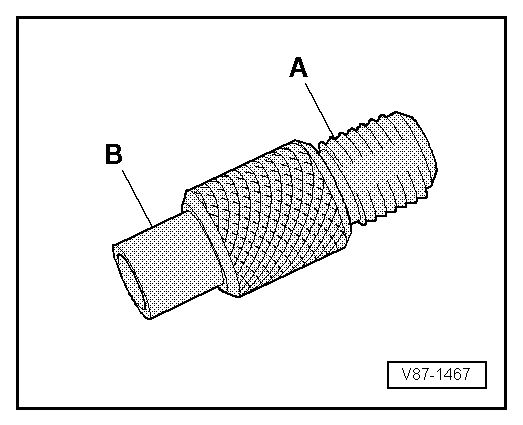

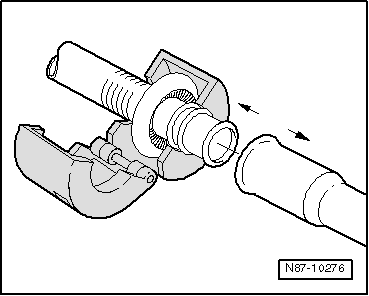

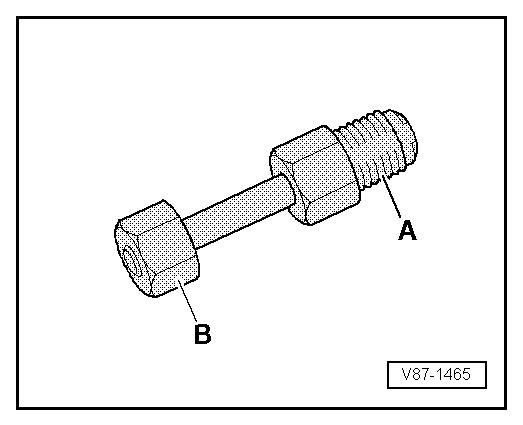

| Adapter set for refrigerant circuit -V.A.G 1785/1-10- |

| Adapter to clean refrigerant circuit (flushing with

refrigerant R134a)

→ Chapter or blowing through with compressed air or

nitrogen

→ Chapter |

| A - |

5/8"-18 UNF thread for conical surface seal |

| B - |

Cap nuts (for connection with O-ring) with thread |

| A - |

5/8"-18 UNF thread for conical surface seal |

| B - |

Threaded union for O-ring |

|

|

|

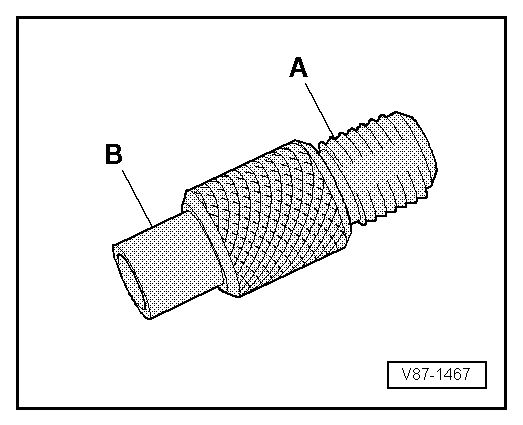

| A - |

5/8"-18 UNF thread for conical surface seal |

| B - |

Internal thread with valve opener M 10x1.25 V.A.G 1785/9

(for connections with valves on the high-pressure side) M 12x1.5

V.A.G 1785/10 (for connections on the low-pressure side) |

Note Note

| There is a Schrader valve screwed into connection

-A-. |

| A valve opener must be fitted into the charging hose

connection. |

|

|

|

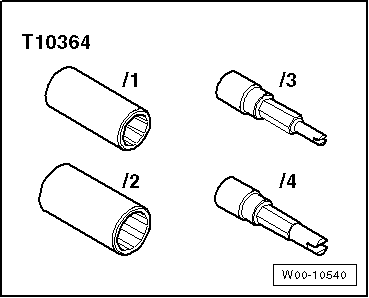

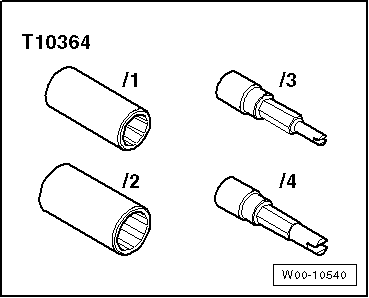

| Socket insert -T10364- for valves of service connections on

HP/LP side of refrigerant circuit |

|

|

|

List of test equipment, tools and materials

Note

This list is an overview of the test equipment, tools and

materials necessary for professional repairs to t ...

Fin comb

Charging hoses

5/8"-18 UNF valve

...

© 2016-2026 Copyright www.vwgolf.org

Note

Note Note

Note Note

Note Note

Note Testing equipment and tools

Testing equipment and tools Tools and materials commercially available

Tools and materials commercially available

Caution

Caution