Volkswagen Golf Service & Repair Manual: Removing and installing valve stem seals (cylinder head installed)

| Special tools and workshop equipment

required |

|

|

|

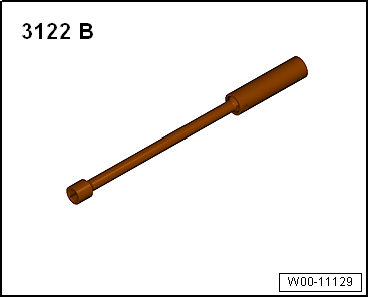

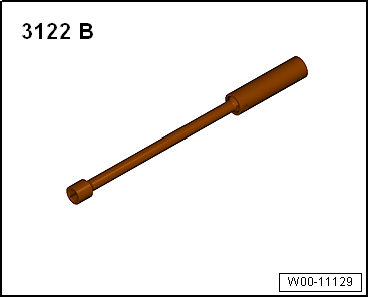

| Spark plug socket and extension -3122 B- |

|

|

|

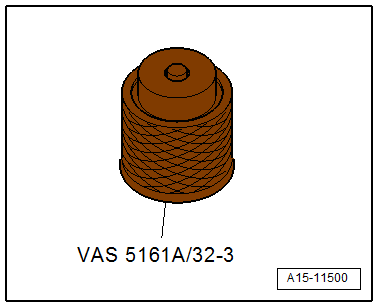

| Removal and installation device for valve cotters -VAS

5161A- with guide plate -VAS 5161A/32-32-. |

| Compressed air adapter -VAS 5161 A/35- (not illustrated) |

|

|

|

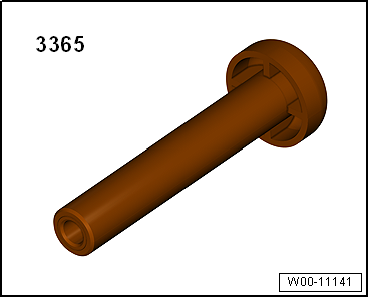

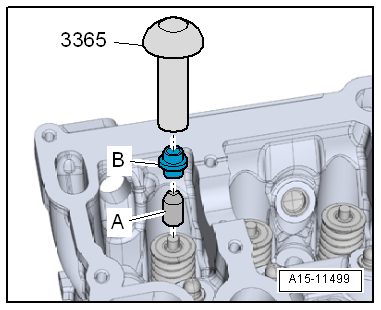

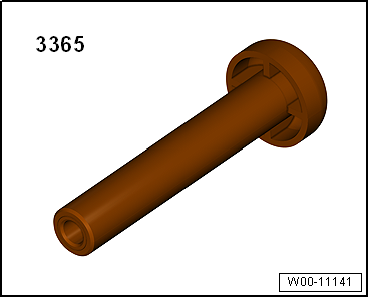

| Valve stem seal fitting tool -3365- |

|

|

|

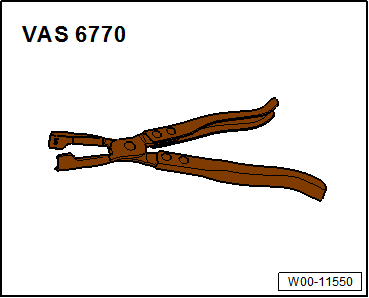

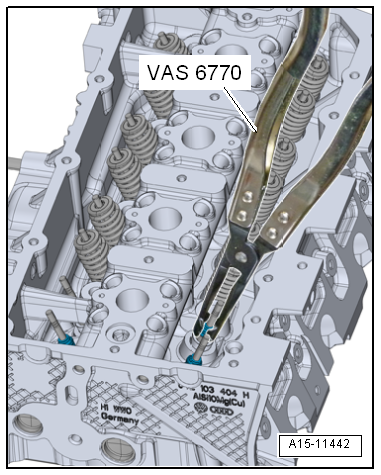

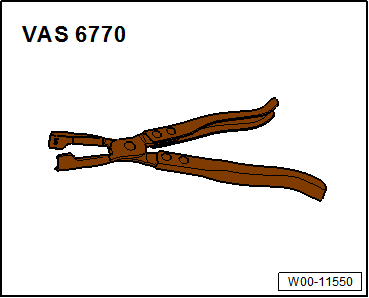

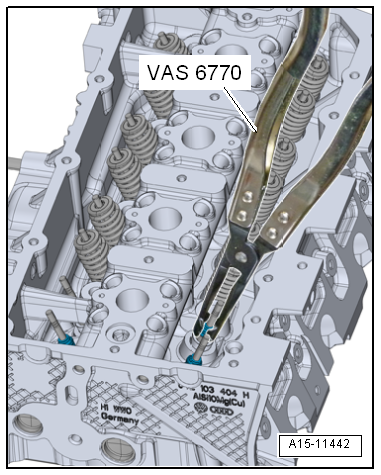

| Valve stem pliers -VAS 6770- |

| – |

Remove plenum chamber cover

→ Rep. gr.50. |

|

|

|

| – |

Remove plenum chamber bulkhead

→ Rep. gr.50. |

|

|

|

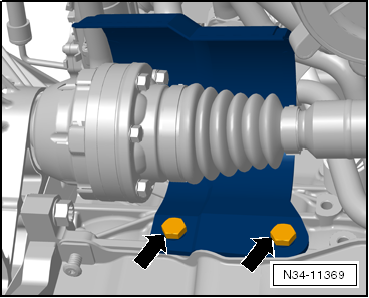

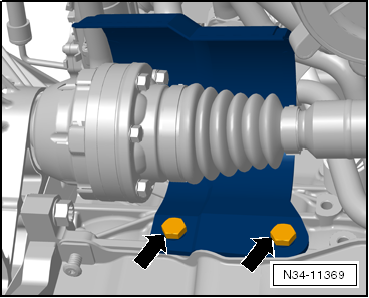

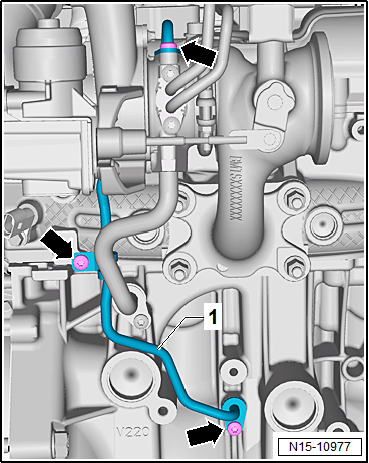

| – |

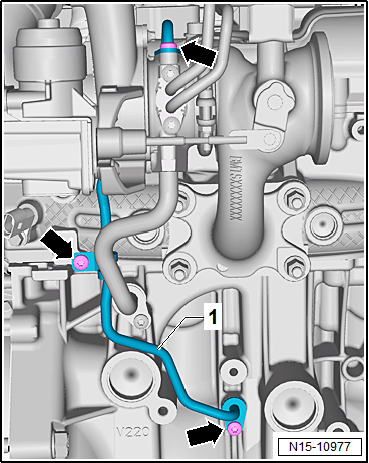

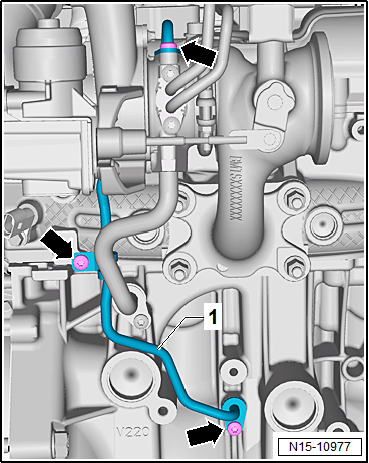

Remove bolts -arrows-. Remove

heat shield from right drive shaft. |

| – |

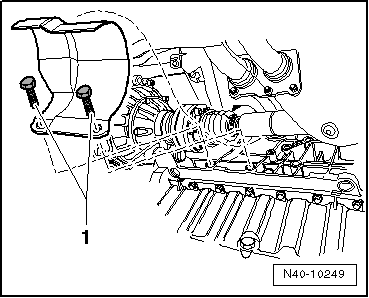

Unscrew bolts -arrows-, and

remove oil supply line -1-. |

| Continuation for all vehicles |

| – |

Remove camshaft housing

→ Chapter. |

| – |

Unscrew spark plugs with spark plug spanner -3122 B-. |

|

|

|

| – |

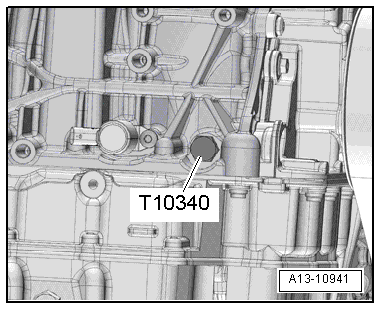

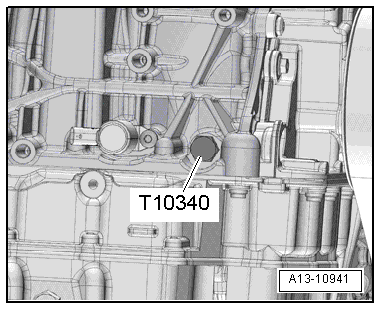

Unscrew locking pin -T10340-. |

| – |

Set piston of respective cylinder to “bottom dead centre”. |

|

|

|

| – |

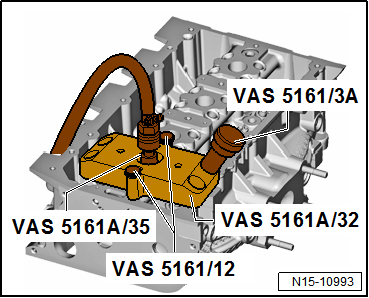

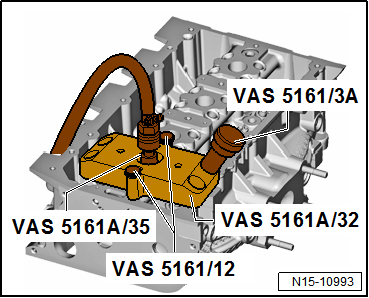

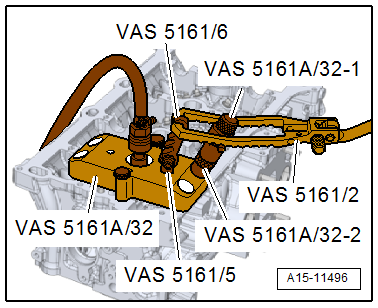

Fit guide plate -VAS 5161A/32-1- onto cylinder head and

secure with knurled screws -VAS 5161/12-. |

| – |

Screw compressed air adapter -VAS 5161 A/35- into the

respective park plug thread hand-tight. |

| – |

Connect adapter to compressed air supply using a

commercially available union and apply pressure continuously. |

| – |

Insert punch -VAS 5161/3A- into guide plate and use a

plastic hammer to knock loose the firmly seated valve cotters. |

|

|

|

| – |

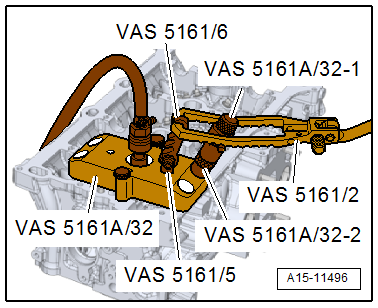

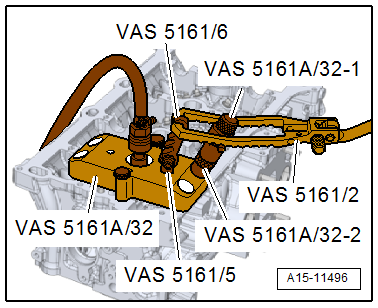

Screw toothed piece -VAS 5161/6- with hooking fork

-VAS 5161/5- into guide plate. |

| – |

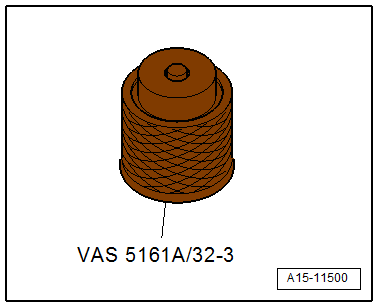

Slide sleeve -VAS 5161A/32-2- onto assembly cartridge and

insert cartridge into guide plate -VAS 5161A/32-3-. |

| – |

Attach pressure fork -VAS 5161/2- to toothed piece and press

assembly cartridge down. |

| – |

At the same time, turn knurled screw of assembly cartridge

clockwise until tips engage in valve cotters. |

| – |

Move knurled screw back and forth to press apart valve

cotters and capture them in assembly cartridge. |

| – |

Remove installation cartridge. |

| – |

Unbolt guide plate and move to side. |

| The compressed air hose remains connected. |

| – |

Remove valve spring and valve spring plate. |

|

|

|

| – |

Pull off valve stem seal using valve stem pliers -VAS 6770-. |

Note Note

| Risk of damage when installing valve stem seals. |

|

|

|

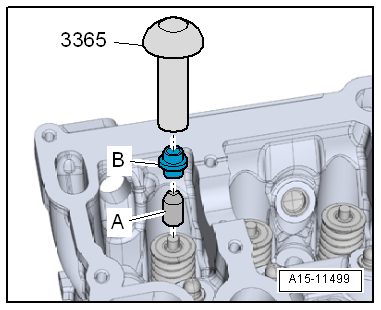

| – |

Place plastic sleeve -A-,

enclosed with new valve stem seals -B-,

onto valve stem. |

| – |

Lightly oil sealing lip of valve stem seal. |

| – |

Push valve stem seal onto plastic sleeve. |

| – |

Carefully press valve stem seal onto valve guide using valve

stem seal fitting tool -3365-. |

|

|

|

| If the valve cotters have been removed from the assembly

cartridge, they must first be inserted into the insertion

device. |

| Larger diameter of valve cotters faces upwards. |

| – |

Press assembly cartridge onto insertion device from above

and pick up valve cotters. |

| – |

Insert valve spring and valve spring plate. For installation

position of valve spring refer to

→ Fig.. |

|

|

|

| – |

Bolt guide plate -VAS 5161A/32-1- onto cylinder head again. |

| – |

Insert assembly cartridge -VAS 5161A/32-2- with sleeve -VAS

5161A/32-3- into guide plate. |

| – |

Press pressure fork downwards and pull knurled screw

upwards, turning it clockwise and anticlockwise. This inserts

the valve cotters. |

| – |

Reduce pressure on pressure fork whilst pulling on knurled

screw. |

| – |

Repeat procedure on each valve. |

| Installation is carried out in the reverse order; note the

following: |

|

|

|

| – |

Install oil supply line -1-,

and tighten bolts -arrows- to 9 Nm. |

| – |

Install plenum chamber bulkhead

→ Rep. gr.50. |

| – |

Install plenum chamber cover

→ Rep. gr.50. |

| Continuation for all vehicles |

| – |

Install spark plugs

→ Booklet. |

| – |

Install camshaft housing

→ Chapter. |

|

|

|

| Component |

Specified

torque |

| Bolts -1- |

25 Nm |

Special tools and workshop equipment

required

Assembly tool -T10479 A-

Removing

...

Special tools and workshop equipment

required

Removal and installation device for valve cotters -VAS

...

© 2016-2026 Copyright www.vwgolf.org

Note

Note Removing and installing exhaust camshaft oil seal, gearbox end, engine codes

CHPA, CMBA, CPVA, CXSA, CZDA, CZCA, CPVB

Removing and installing exhaust camshaft oil seal, gearbox end, engine codes

CHPA, CMBA, CPVA, CXSA, CZDA, CZCA, CPVB Removing and installing valve stem seals (cylinder head removed)

Removing and installing valve stem seals (cylinder head removed)