Volkswagen Golf Service & Repair Manual: Removing and installing sealing flange on pulley end

| Special tools and workshop equipment

required |

| Sealant

→ Electronic Parts Catalogue |

| – |

Remove noise insulation

→ General body repairs, exterior; Rep. gr.66. |

| – |

Remove air conditioner compressor with refrigerant lines

connected, and tie it up on the right side

→ Heating, air conditioning; Rep. gr.87. |

| – |

Remove toothed belt

→ Chapter. |

|

|

|

| – |

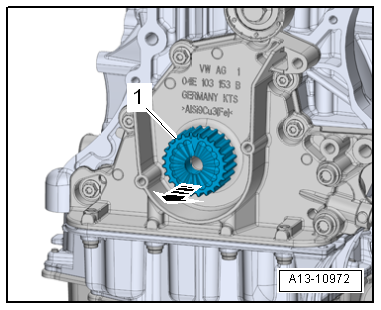

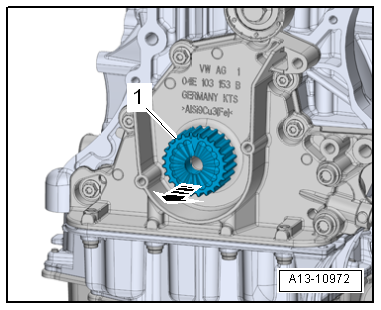

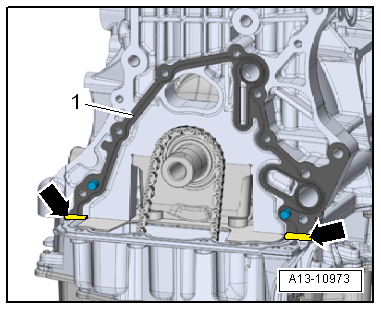

Detach crankshaft pulley -1--arrow-. |

Risk of damage to engine caused by incorrect valve timing.Do not turn

crankshaft out of TDC position.

|

|

|

| – |

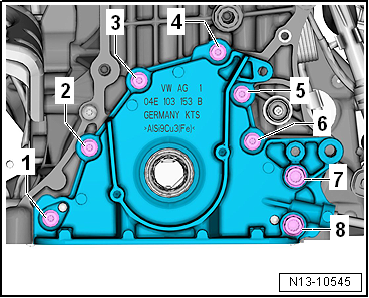

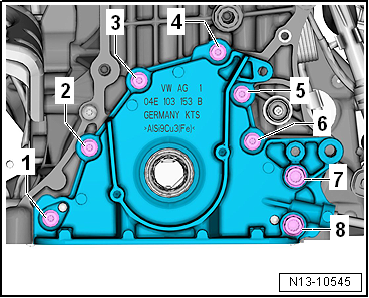

Unscrew bolts -1 … 8- and

carefully remove sealing flange from the glued joint. |

| – |

Drive out seal with sealing flange removed. |

| Installation is carried out in the reverse order; note the

following: |

| The lubrication system can be soiled by sealant residue. |

| Cover open section of sump with clean clothes. |

| – |

Remove sealant residue from sealing flange and sump (top

section). |

| – |

Remove any oil and grease from sealing surfaces. |

Note Note

|

|

|

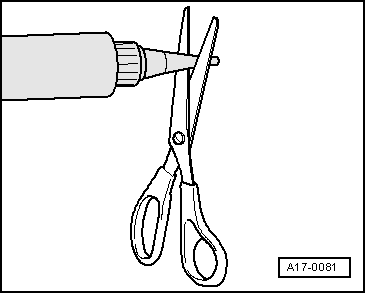

| Observe use-by-date of sealant. |

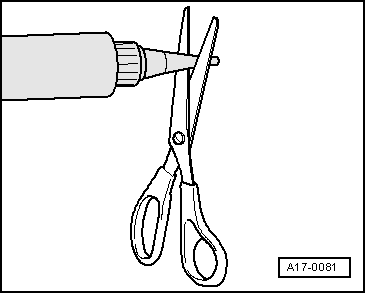

| – |

Cut off nozzle on tube at front marking (diameter of nozzle

approx. 2 mm). |

|

|

|

| – |

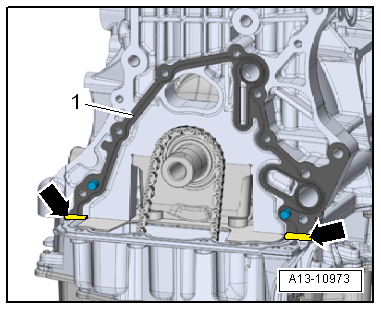

Slide gasket -1- onto dowel

pins in cylinder block. |

| – |

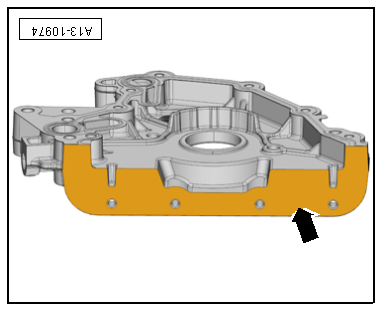

Apply a thin bead of sealant at the edge of the joint

between the cylinder block and the sump

-arrows-. |

|

|

|

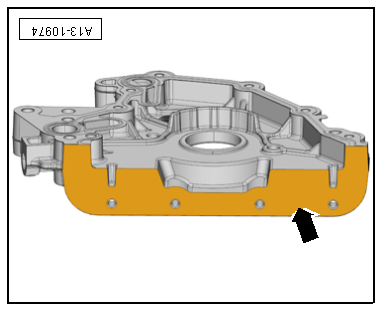

| – |

Thinly coat lower sealing surface

-arrow- of sealing flange with sealant. |

Note Note

| Install the sealing flange within 5 minutes after the

sealant has been applied. |

| – |

Carefully fit gasket sealing flange onto dowel pins on

cylinder block. |

| – |

Tighten bolts for sealing flange

→ Fig.. |

| – |

Install crankshaft oil seal on belt pulley end

→ Chapter. |

|

|

|

| – |

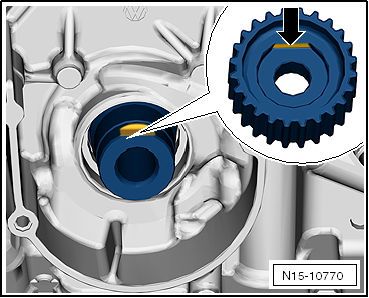

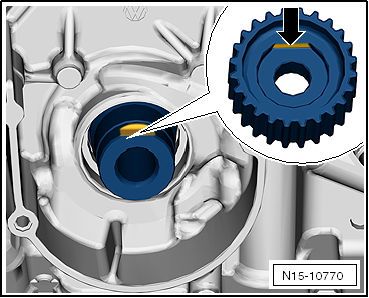

Fit crankshaft sprocket onto crankshaft. |

| The contact surface between vibration damper and crankshaft

pulley must be free of oil and grease. |

| The machined surface -arrow- of

crankshaft pulley must be positioned over the machined surface

of the crankshaft journal. |

| – |

Install toothed belt (adjust valve timing)

→ Anchor. |

| – |

Install air conditioner compressor

→ Heating, air conditioning; Rep. gr.87. |

| – |

Install noise insulation

→ General body repairs, exterior; Rep. gr.66. |

| → Fig. „“Sealing flange at belt pulley end - Prescribed torque

and tightening sequence”“ |

| → Heating, air conditioning; Rep. gr.87 |

|

|

|

Special tools and workshop equipment

required

Assembly tool -T10485-

...

Other materials:

Round connector systems

Note

If necessary, any housing catches in place (secondary

locking mechanisms) must be released or removed prior to

disengaging the contacts using the prescribed tool

→ Chapter.

...

Spraying the evaporator with the suction feed spray-gun -V.A.G 1538- and

spray lance

Spray the evaporator with Contra Sept directly using a spray

lance (approx. 10 bar). Contra Sept neutralises microbes and

bacteria directly at the evaporator.

In order to enable access to the evaporator, some

preliminary work and differe ...

Electrical controls on the front seats

Fig. 44 Moving the front left seat forwards

and backwards, adjusting the backrest and the seat cushion for height and tilt

Fig. 45 Adjusting the lumbar support.

First read and observe the introductory information

and safety warnings The layout of the controls on the front right-hand seat ...

© 2016-2024 Copyright www.vwgolf.org

Note

Note Note

Note Renewing crankshaft oil seal - belt pulley end

Renewing crankshaft oil seal - belt pulley end