Volkswagen Golf Service & Repair Manual: Removing and installing brake system pressure accumulator -VX70-, LHD

vehicles

| Special tools and workshop equipment

required |

|

|

|

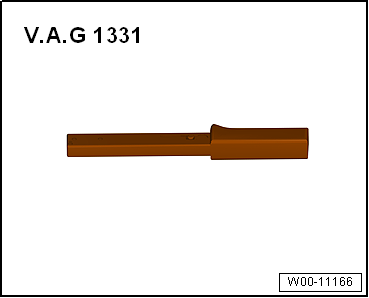

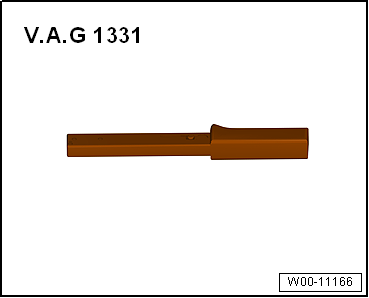

| Torque wrench -V.A.G 1331- |

|

|

|

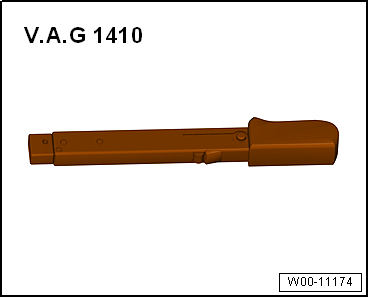

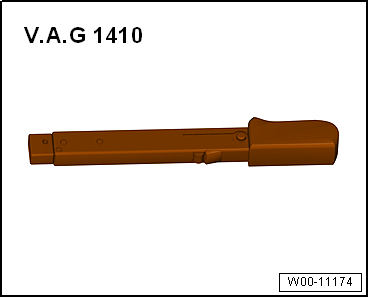

| Torque wrench -V.A.G 1410- |

| Tool inserts (11 mm) -V.A.G 1331/2- |

|

|

|

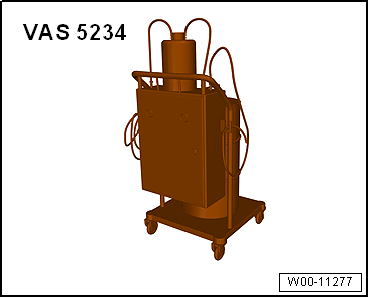

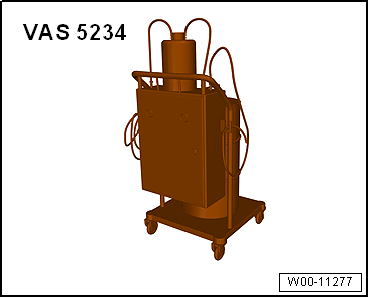

| Brake filling and bleeding equipment -VAS 5234- |

|

|

|

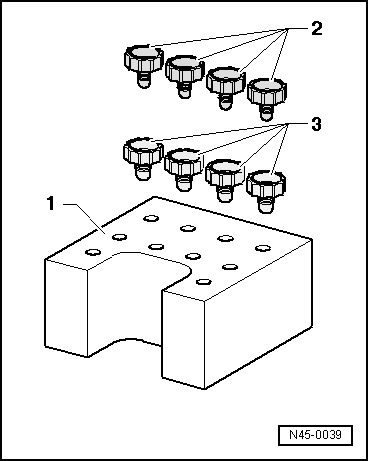

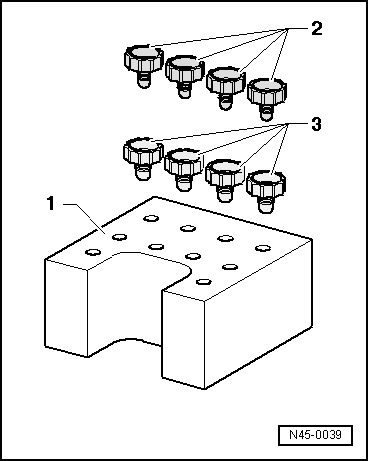

| Sealing plug repair kit -1H0 698 311 A- |

|

|

|

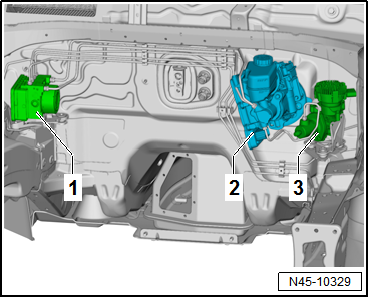

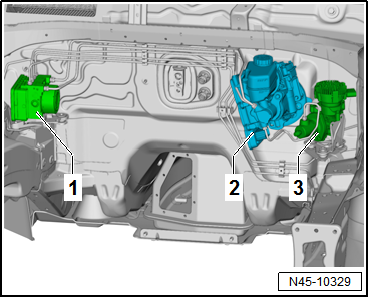

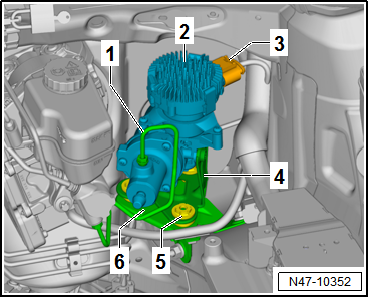

| 2 - |

Brake servo and brake master cylinder |

| 3 - |

Brake system pressure accumulator -VX70- |

| – |

Observe safety precautions when working in the area of

high-voltage components

→ Chapter. |

| – |

Observe the risk classification of the high-voltage system

→ Electric drive; Rep. gr.00. |

|

|

|

| Danger to life due to high voltage |

| The high-voltage system is under high voltage. If high-voltage

components are damaged, there is a risk of severe or fatal injury due to

electric shock. |

| – |

Carry out visual inspection of high-voltage components and cables. |

| – |

Never use cutting or forming tools, or any others with sharp edges. |

| – |

Never use heat sources such as welding, soldering, thermal bonding

or hot air. |

| – |

Disconnect battery

→ Electrical system; Rep. gr.27. |

| – |

Remove power and control electronics for electric drive

-JX1-

→ Electrical system; Rep. gr.93. |

| – |

Remove bracket for power and control electronics for

electric drive -JX1-

→ Electrical system; Rep. gr.93. |

| – |

Draw off as much brake fluid as possible from brake fluid

reservoir using brake filling and bleeding equipment -VAS 5234-. |

| – |

Place sufficient lint-free cloths in the area of the brake

system pressure accumulator -VX70--1-. |

|

|

|

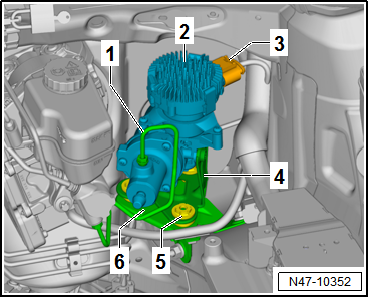

| – |

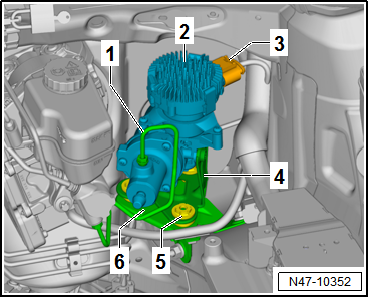

Unscrew brake line -1- from

brake system pressure accumulator -VX70--2-. |

| – |

Seal threaded hole immediately using sealing plugs -1H0 698

311 A-. |

| – |

Fit a dust cap from the bleeder valve onto brake line. |

| – |

Pull brake system pressure accumulator -VX70--2-

together with bracket -4- and

rubber dampers -5- upwards off

bracket -6-. |

| – |

Slightly tilt brake system pressure accumulator -VX70-, then

release and pull off connector -3-. |

| Install in reverse order. Note the following points: |

|

|

|

| – |

Ensure rubber dampers -5- are

seated correctly in bracket -4- of

brake system pressure accumulator -VX70-. |

| – |

Ensure that retaining pins have been fully and evenly

inserted into rubber dampers. |

| – |

Ensure secure seating by pulling. |

| Ensure that rubber dampers of retainer are not pressed out

of bracket when installing. After installation, check that the

brake system pressure accumulator -VX70- is securely seated,

otherwise malfunction can occur. |

| – |

Bleed brake system

→ Chapter. |

| – |

Subsequently bleeding the brake system

→ Chapter. |

| – |

Perform basic setting for electromechanical brake servo

→ Vehicle

diagnostic tester. |

| → Chapter „Assembly overview - brake servo/brake master

cylinder, LHD vehicles“ |

| → Chapter „Assembly overview – Brake system pressure accumulator

-VX70-“ |

| → Electrical system; Rep. gr.93 |

| → Electrical system; Rep. gr.27. |

|

|

|

Special tools and workshop equipment

required

Torque wrench -V.A.G 1331-

...

Special tools and workshop equipment

required

Torque wrench -V.A.G 1331-

...

Other materials:

Indicator lamp

First read and observe the introductory information

and safety warnings

Lit up

Possible cause

Solution

Engine management system fault (Electronic Power Control).

The engine should be checked by a qualified workshop

as s ...

Checking shock absorbers when removed

Defective shock absorbers can be identified by loud rumbling

noises when driving, caused by wheel hopping, especially on bad

roads. Heavy fluid leakage is an additional visual indication.

Note

Shock absorbers are maintenance-fre ...

Assembly overview - rear window washer system, GTI and GTD

1 -

Connection for high-level brake light

2 -

Connection for washer fluid hose

For rear window washer system.

3 -

Water line

Leading to spray jet of rear window washer system; location: ...

© 2016-2024 Copyright www.vwgolf.org

Removing and installing brake master cylinder, RHD vehicles

Removing and installing brake master cylinder, RHD vehicles Removing and installing brake system pressure accumulator -VX70-, RHD

vehicles

Removing and installing brake system pressure accumulator -VX70-, RHD

vehicles