Volkswagen Golf Service & Repair Manual: Notes on treating corroded fold areas

| Examples for corrosion in the fold area of bonnet, door or

rear lid |

| – |

Remove corrosion using

→ Chapter „Pneumatic brush grinder set -VAS 6446-“ or

→ Chapter „Brush grinder set -VAS 6776-“. |

| – |

Smooth off transitions using sandpaper (P360 to P400 grade). |

| – |

Clean substrate using silicon remover. |

| – |

After a corrosion damage has been repaired and before

sealing, isolate substrate using 2-pack wash primer -LHV 043 000

A2-, and then apply 2-pack HS Performance surfacer. |

| – |

As soon as the surfacer is completely dry, treated areas

must be dry-sanded using P400 to P500 sandpaper. When sanding,

take particular care not to “sand through”. Afterwards, clean

sanded surfaces with silicon remover. |

| – |

After sanding the dry surfacer, the metal edges in the fold

area must be sealed with fine seam sealant

→ Chapter „Sealing materials“. Ensure that the fine

seam seals are identical in appearance to the original seam

seals, as specified in the

→ »Vehicle-specific paintwork information« for the

particular vehicle. |

Note Note

| |

Seam seals made during repair work must be identical in

appearance and thickness to the original seam seals. |

| |

To avoid damage or faulty operation, brush seam seals smooth

near attachments which must be attached. |

| |

Water drainage holes must remain clear. |

| |

All threaded studs and welded nuts with metric threads as

well as all other studs and contact surfaces for assembly must

be functional following the extent of the sealing work. |

| |

Sealant must never be applied to bare metal. Substrates must

always be coated with surfacer first. |

| – |

Restore paintwork structure according to the paintwork

repair manual. |

| – |

Apply cavity sealant along entire fold area using

→ Chapter „Suction feed spray-gun -V.A.G 1538-“;

→ Chapter „Anti-corrosion materials“. |

Note Note

| The repair can only be considered successful if the fold

area is sealed air-tight from inside (so that no ingress of

moisture is possible). |

|

|

|

| |

|

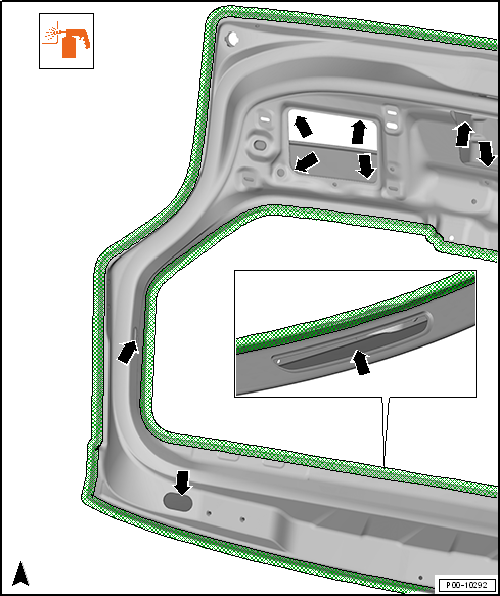

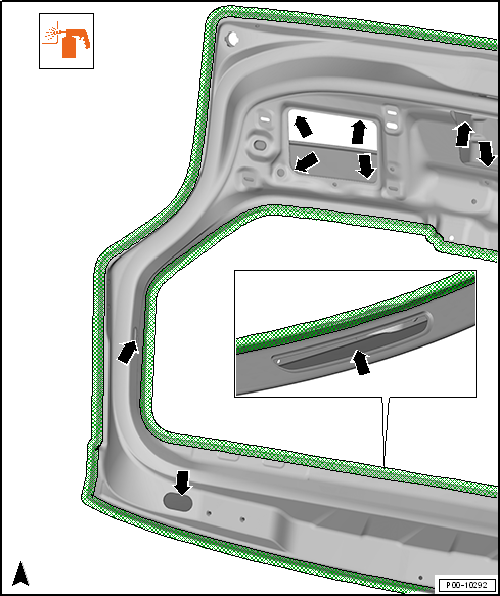

Cavity sealing, rear lid |

| |

|

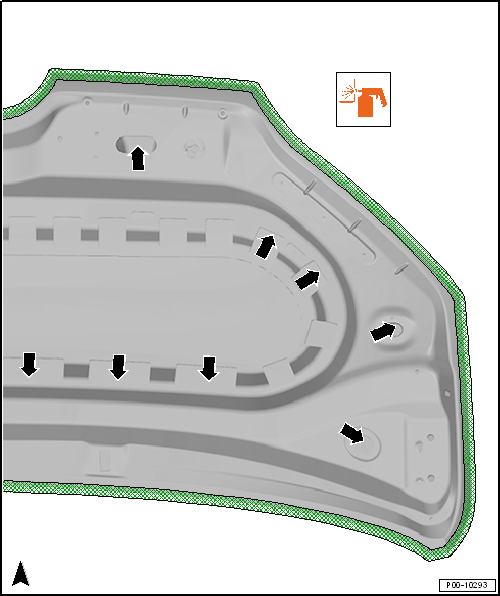

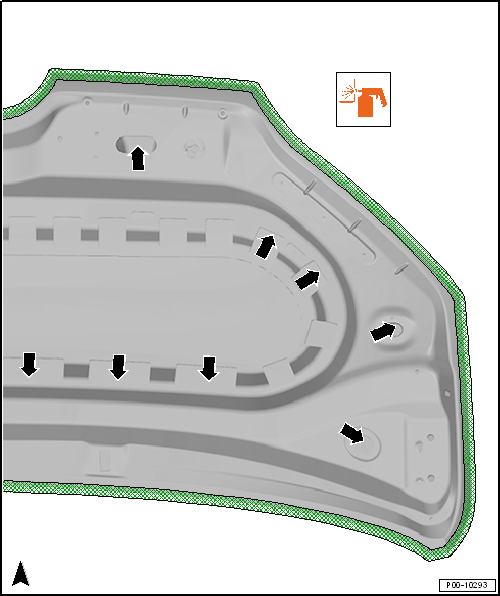

Cavity sealing, bonnet |

| |

|

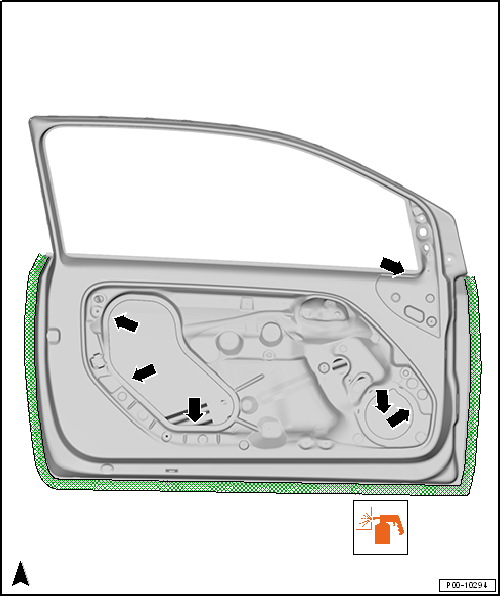

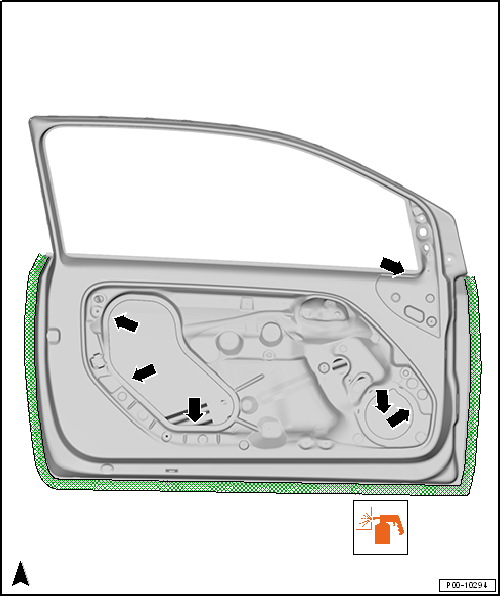

Cavity sealing, door |

Note

The corrosion protection measure is to be carried out in the groove

of the wing of all new replacement parts which have not had the

additional sealant applied ...

Attachments

Wings, doors, covers and flaps must be coated completely on

the inside as well. One wet-in-wet spray pass is adequate for

...

Other materials:

Matting additive -LVM 769 810 A2

Designation:

Matting additive -LVM 769 810 A2-

Issued 10.2014

Product description

The matting additive -LVM 769 810 A2- is an additive for

2-pack HS clear coats and 2-pack HS ...

Assembly overview - alternator without sliding bushes

1 -

Bolt

Qty. 4

Specified torque: 23 Nm

2 -

Alternator -C-

Removing and installing

→ Chapter

Checking

→ Chapter

Removing and instal ...

Tack cloth -VAS 6177

Designation:

Tack cloth -VAS 6177-

Product description:

Tack cloth with extremely effective soft tack properties for

critical cleaning tasks. Unlike other tack cloths, this cloth

does not lea ...

© 2016-2026 Copyright www.vwgolf.org

Note

Note Note

Note Corrosion protection measures for wing surface in contact with wheel housing

liner

Corrosion protection measures for wing surface in contact with wheel housing

liner Corrosion protection for body components, add-on components and welded

components

Corrosion protection for body components, add-on components and welded

components