Volkswagen Golf Service & Repair Manual: Mounting tyre, run-flat tyres, ultra-high performance tyres

| Only trained personnel may perform any assembly work on

run-flat tyres and ultra-high-performance tyres. |

| If fitted, check tyre pressure sensor using vehicle

diagnostic tester, and renew it as necessary. |

| – |

Ensure proper assembly temperature for tyres

→ Chapter. |

Note Note

| If bonded wheel trims are fitted, treat them with great

care. The surface is susceptible to scratches. |

| If the wheel trim is damaged, renew wheel rim. |

| – |

Insert new tyre valve using valve fitting tool -VAS 6459-. |

| – |

Liberally apply tyre assembly paste to wheel rim flanges,

tyre beads and inner side of the upper tyre beads. |

| – |

Place tyres with inner side facing downwards onto wheel rim. |

|

|

|

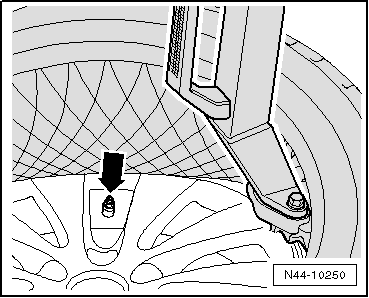

| – |

Turn wheel rim, until tyre valve or tyre pressure sensor are

positioned opposite to assembly head. |

|

|

|

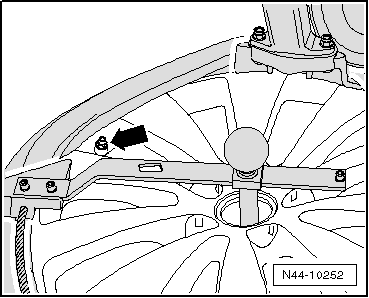

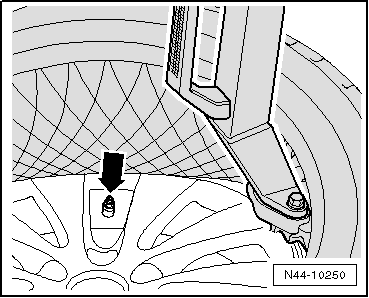

| – |

Run tyre fitting unit clockwise until assembly head is

positioned before tyre valve or tyre pressure sensor

-arrow-. The lower tyre bead will

now slide over the wheel flange. |

|

|

|

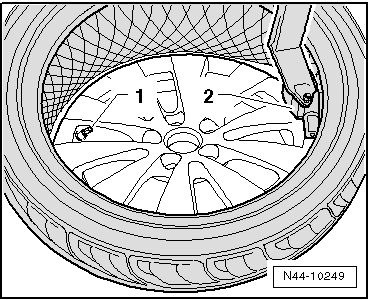

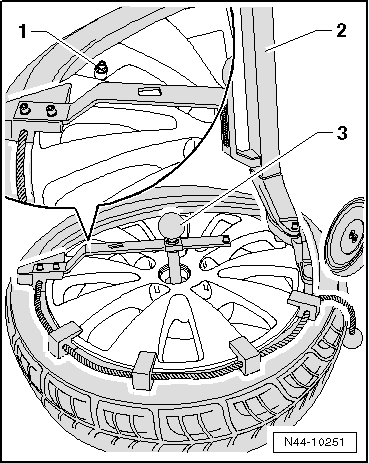

| – |

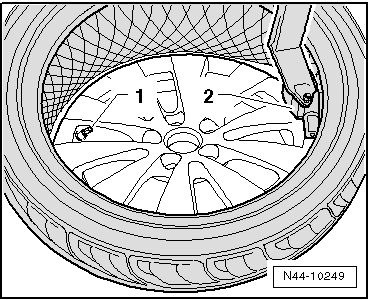

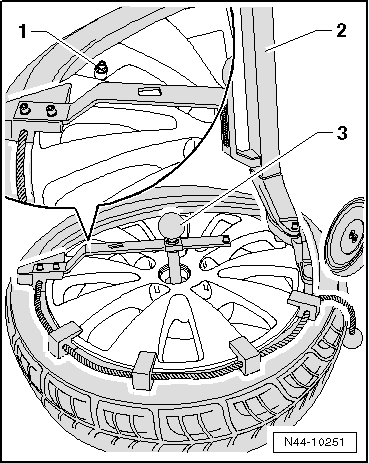

Turn wheel rim, until tyre valve or tyre pressure sensor

-1- are positioned opposite to

assembly head -2-. |

| – |

Insert depressor -3- on the

wheel rim. |

|

|

|

Only trained personnel may perform any assembly work on

run-flat tyres.

If fitted, check tyre pressure sensor using vehicle

diagnos ...

If necessary, eliminate flat spots caused by storage or

handling

→ Chapter.

–

Press tyre off wheel rim

→&n ...

© 2016-2024 Copyright www.vwgolf.org

Note

Note Note

Note Mounting tyre, wheels without and with tyre pressure monitoring

Mounting tyre, wheels without and with tyre pressure monitoring Matching wheel rims and tyres

Matching wheel rims and tyres

Caution

Caution