Volkswagen Golf Service & Repair Manual: Dismantling and assembling drive shaft, constant velocity joint VL107

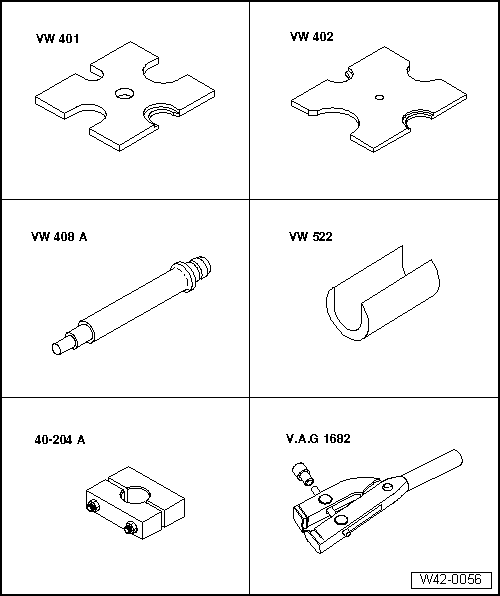

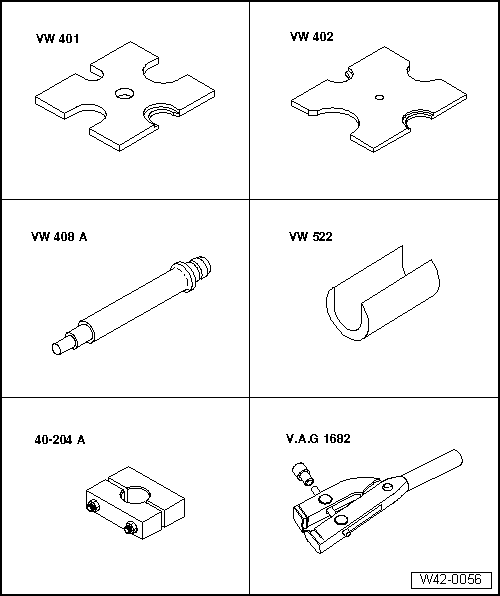

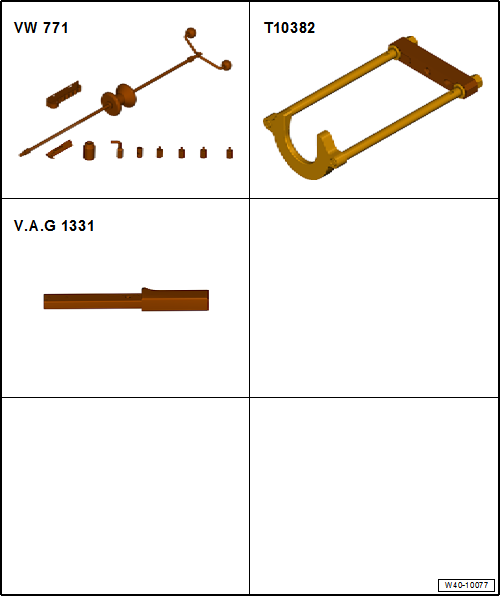

| Special tools and workshop equipment required |

| Special pliers -V.A.G 1682- |

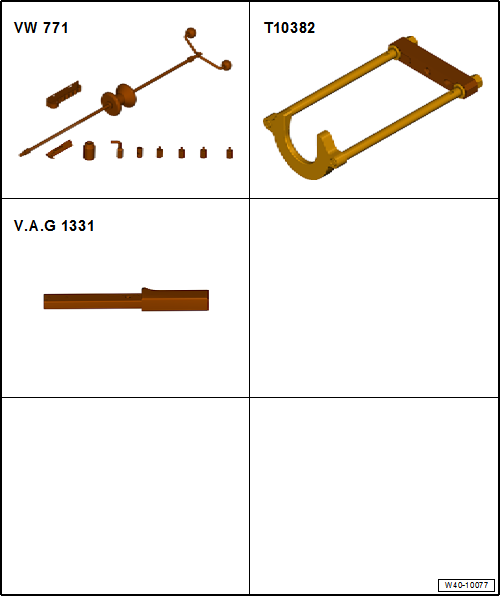

| Multi-purpose tool -VW 771- |

| Torque wrench -V.A.G 1331- |

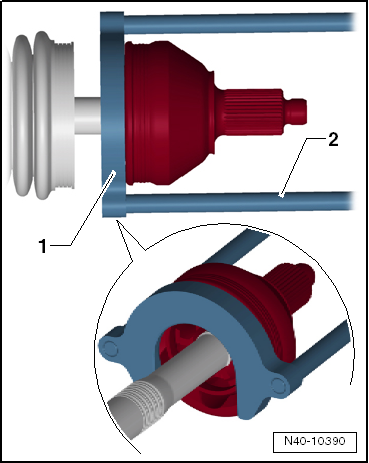

| Removing outer constant velocity

joint |

| – |

Clamp drive shaft in vice using protective jaw covers. |

| – |

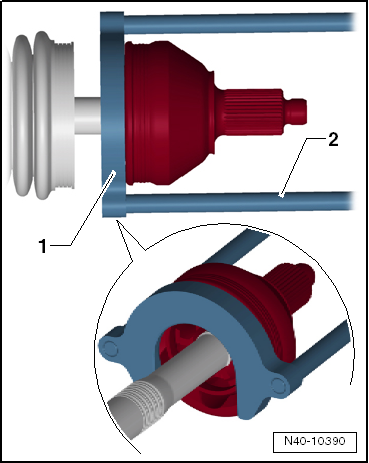

Set puller -T10382- up so that smooth side of puller plate

-T10382/1- points to spindles -T10382/2-. |

| – |

Assemble puller -T10382- complete with multi-purpose tool -VW

771-. |

|

|

|

| – |

Pull constant velocity joint from drive shaft with puller

-T10382- and multi-purpose tool -VW 771-. |

| 1 - |

Puller plate -T10382/1- |

| Driving on outer constant velocity joint |

| – |

Install new retaining ring. |

| – |

If necessary, push new joint boot onto drive shaft. |

| – |

Knock onto shaft with plastic hammer until circlip engages. |

|

|

|

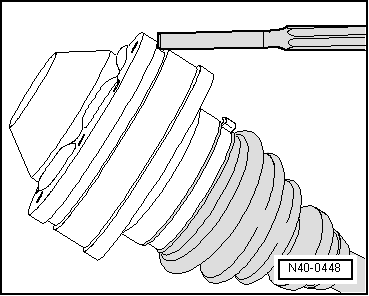

| Driving off cover for inner joint |

| – |

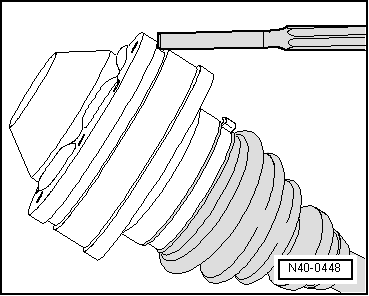

Remove both clamps and slide boot towards outer joint. |

| – |

Drive off joint boot with a drift. |

|

|

|

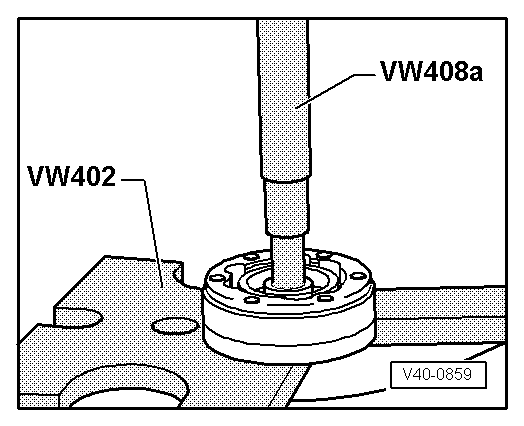

| Pressing off inner constant velocity joint |

|

|

|

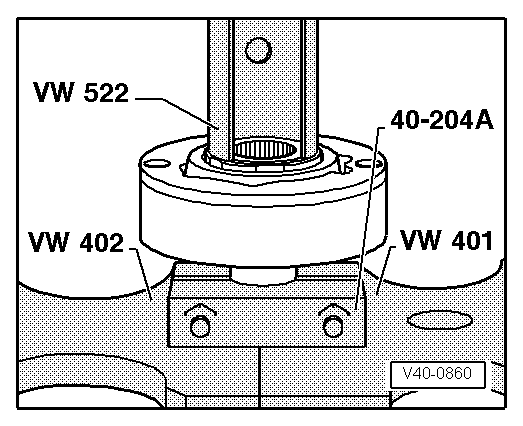

| Pressing on inner constant velocity joint |

| – |

Press joint on to stop. |

| – |

Install retaining ring. |

|

|

|

| – |

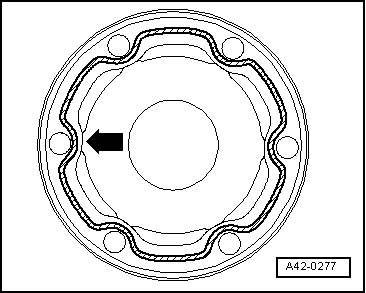

Coat sealing surface of cover with -D 454 300 A2-.

|

| – |

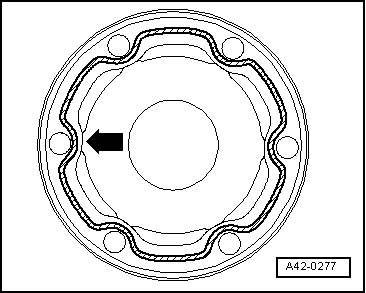

Apply a continuous bead of sealant with a diameter of 2 ...

3 mm to clean surface of cover in area of inner holes

-arrow-. |

|

|

|

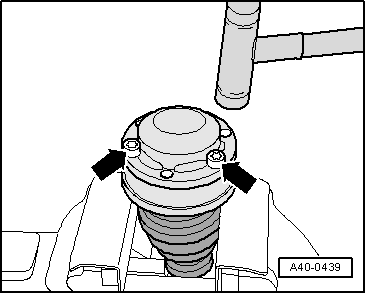

| – |

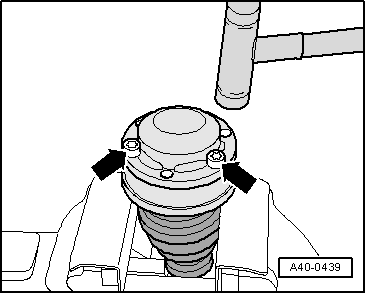

Using bolts -arrows-, align new

cover in relation to bolt holes. |

| The alignment must be very accurate, because no further

alignment is possible once the part has been hammered on. |

| – |

Drive on cover using a plastic hammer. |

| – |

Wipe off surplus sealant. |

|

|

|

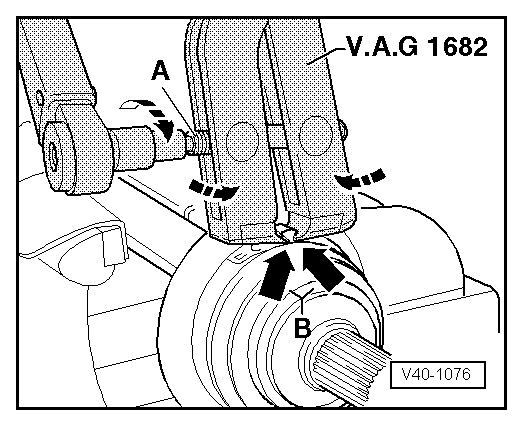

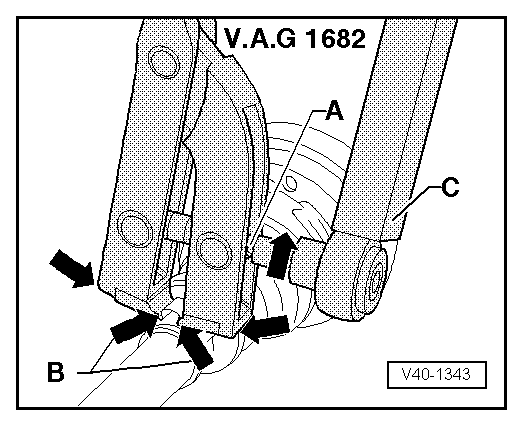

| Tighten clamp on outer joint |

| – |

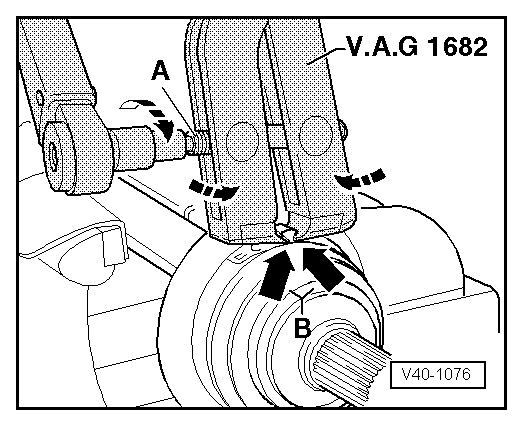

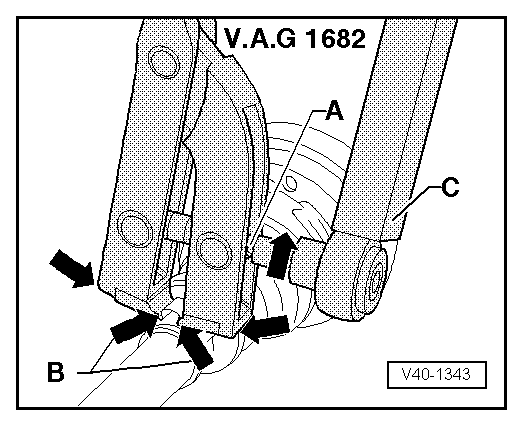

Apply special pliers-V.A.G 1682-

as shown in diagram. Ensure jaws of tensioner lie in corners

-arrows B- of ear on O-type clip. |

| – |

Tighten clamp by turning spindle with a torque wrench (do

not cant pliers).

|

Note Note

| Due to the hard material of the protective boot (compared to

rubber) and the necessity of using a stainless steel clamp, it

is only possible to tension the clamp with clamp tensioner -V.A.G

1682-. |

| Use torque wrench -C - with

setting range of 5 ... 50 Nm (e.g. torque -V.A.G 1331-). |

| Make sure thread of spindle -A-

on pliers moves freely. Lubricate with MoS2 grease if necessary. |

| If the thread is tight (e.g. due to dirt), the required

clamping force for the clamp will not be attained although the

specified tightening torque is applied. |

|

|

|

| Tightening clamp on small diameter |

| Checking outer constant velocity joint

→ Chapter |

| Checking inner constant velocity joint

→ Chapter |

| Checking function of constant velocity joint

→ Anchor |

|

|

|

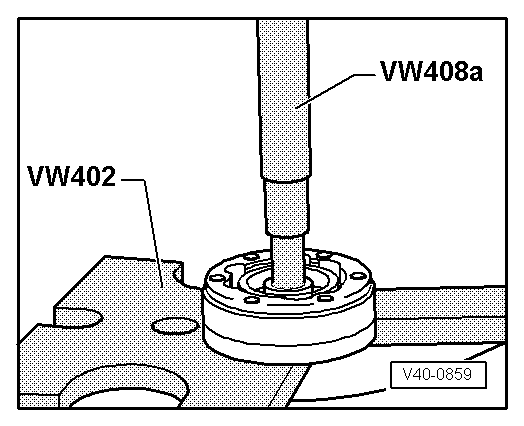

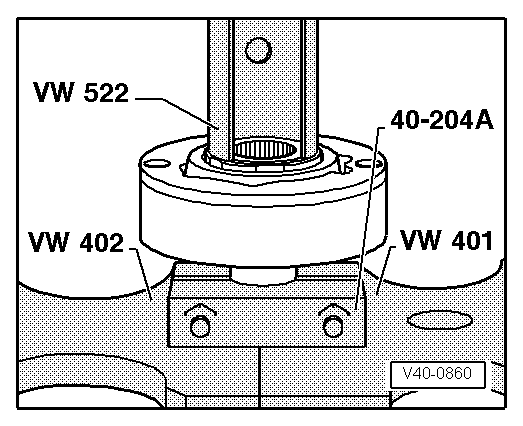

Special tools and workshop equipment required

Thrust plate -VW 401-

Thrust plate -VW 402-

Press tool -VW 408 A-

Press t ...

Special tools and workshop equipment required

Thrust plate -VW 401-

Thrust plate -VW 402-

Press tool -VW 408 A-

...

Other materials:

Contact corrosion

Contact corrosion can occur if unsuitable connecting

elements (screws, bolts, nuts, washers, etc.) are used.

For this reason, only connecting elements with a special

surface coating are fitted in the vehicle.

Moreover, c ...

Bringing air conditioning system into service after charging

Note

If the air conditioner compressor was removed, the V-belt

pulley /freewheel must be turned by hand approx. 10 times prior

to initial operation. This prevents any damage occurring from a

fluid hammer in the air conditioner compressor when th ...

Removing and installing brake caliper

Special tools and workshop equipment

required

Torque wrench -V.A.G 1331-

Brake pedal depressor -V.A.G 1869/2-

& ...

© 2016-2024 Copyright www.vwgolf.org

Note

Note Dismantling and assembling drive shaft, constant velocity joint VL100

Dismantling and assembling drive shaft, constant velocity joint VL100 Dismantling and assembling drive shaft, triple roller joint AAR3300i

Dismantling and assembling drive shaft, triple roller joint AAR3300i