Volkswagen Golf Service & Repair Manual: Dismantling and assembling drive shaft

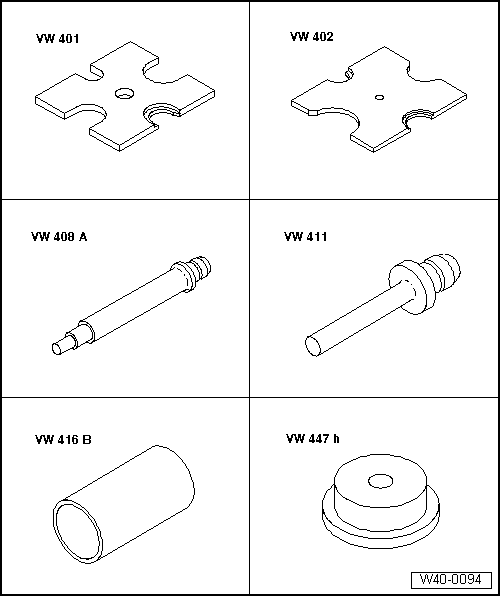

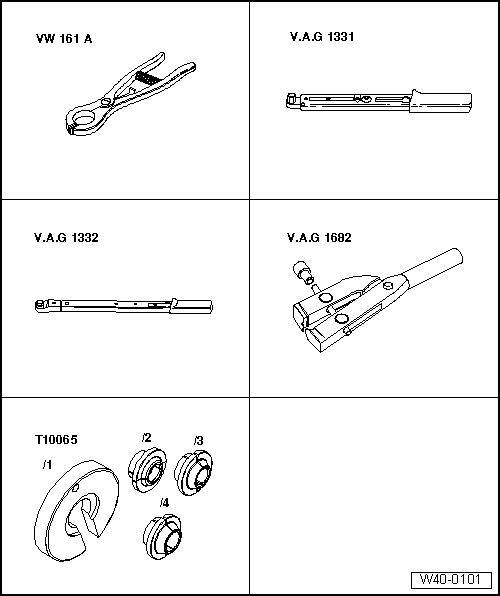

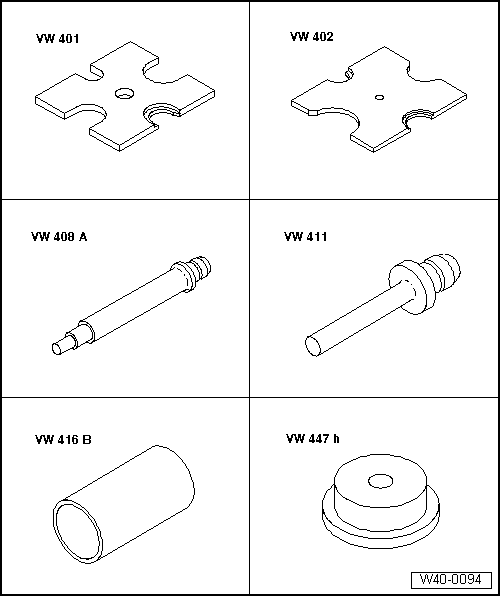

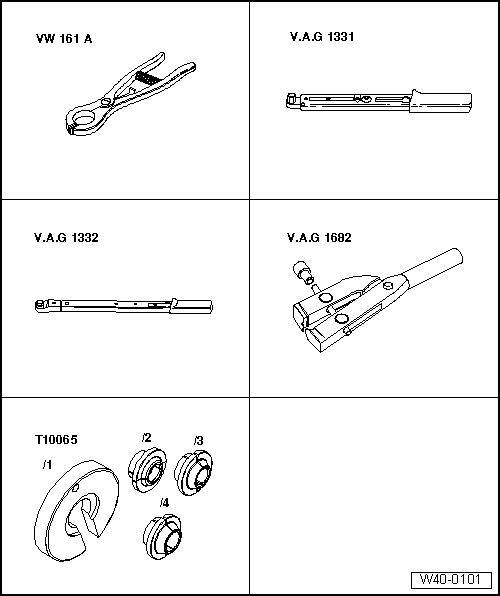

| Special tools and workshop equipment required |

| Circlip pliers -VW 161 A- |

| Torque wrench -V.A.G 1331- |

| Torque wrench -V.A.G 1332- |

| Special pliers -V.A.G 1682- |

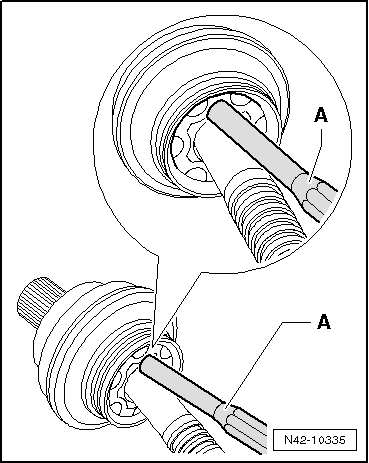

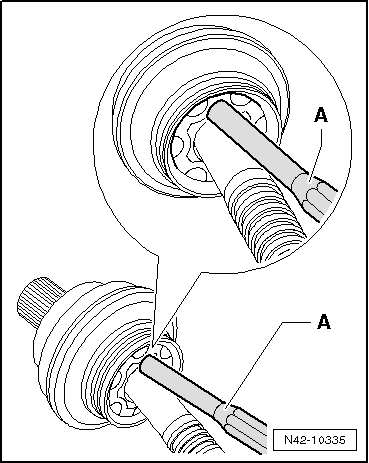

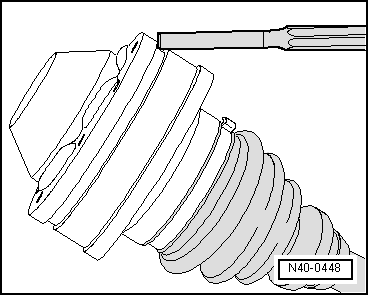

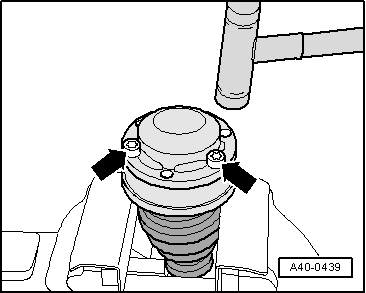

| Driving off outer constant velocity joint |

| – |

Clamp drive shaft in vice using protective jaw covers. |

| – |

Drive constant velocity joint off drive shaft using drift

-A-. |

| Drift must be positioned exactly on ball hub of constant

velocity joint. |

|

|

|

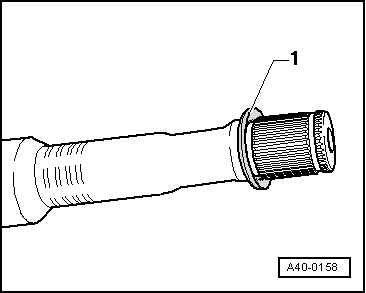

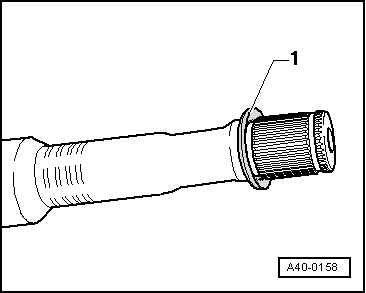

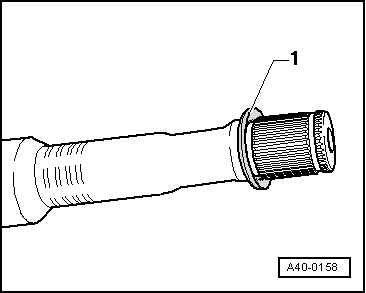

| Installation position of dished spring at outer joint |

| – |

Use plastic-headed hammer to drive joint onto shaft until

circlip engages. |

|

|

|

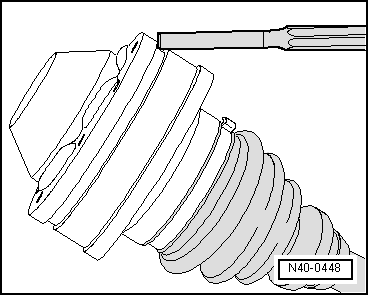

| Driving off cover for inner joint |

|

|

|

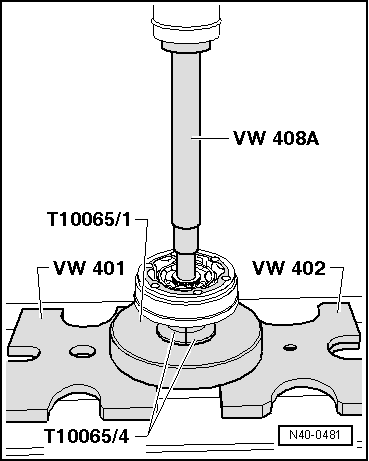

| Pressing off inner constant velocity joint |

| – |

Press off protective boot off joint using a drift. |

| – |

Remove both clamps and slide boot towards outer joint. |

|

|

|

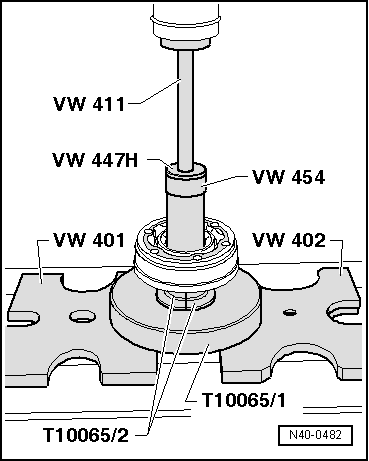

| Installation position of dished spring at inner joint |

|

|

|

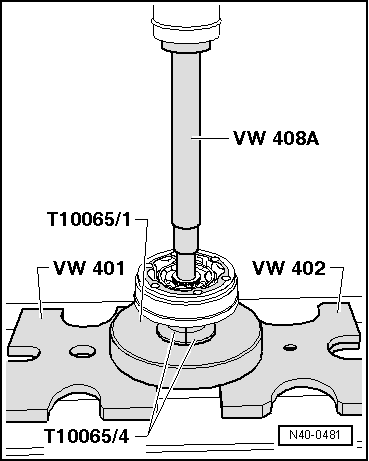

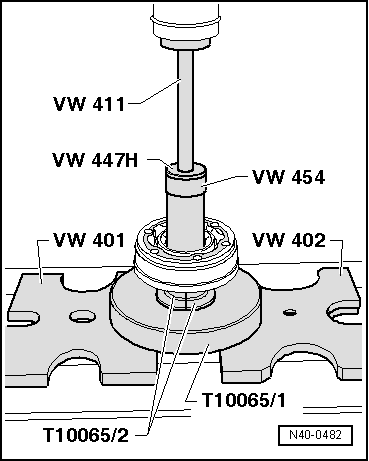

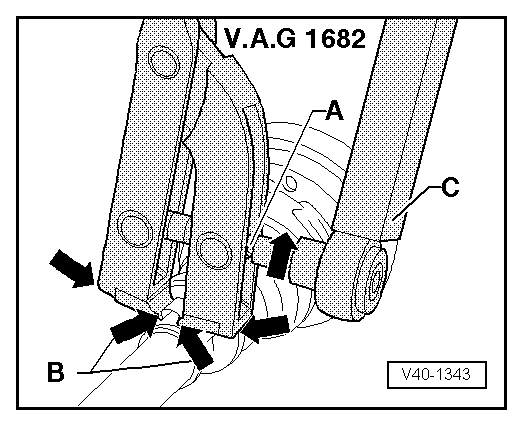

| Pressing on inner constant velocity joint |

Note Note

| Chamfer on internal circumference of ball hub (splines) must

face contact shoulder on drive shaft. |

| – |

Press joint on to stop. |

| – |

Install retaining ring. |

|

|

|

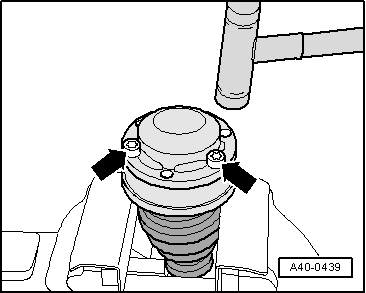

| – |

Using bolts -arrows-, align new

cover in relation to bolt holes. |

| The alignment must be very accurate, because no further

alignment is possible once the part has been hammered on. |

| – |

Drive on cover using a plastic hammer. |

|

|

|

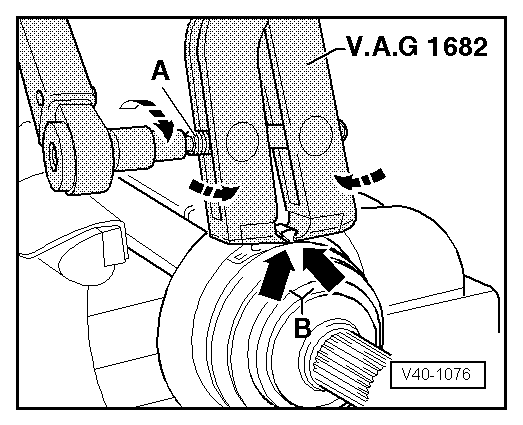

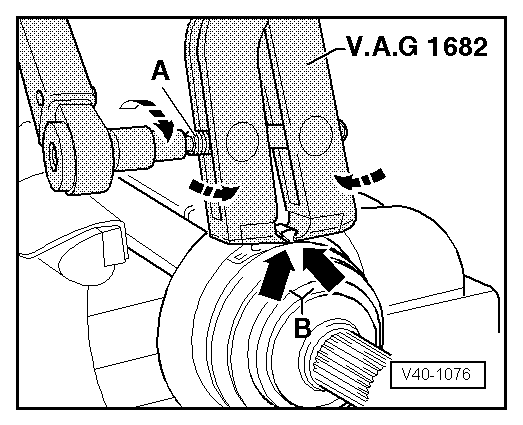

| Tighten clamp on outer joint |

| – |

Position clamp tensioner -V.A.G 1682- as shown in diagram.

Ensure jaws of tensioner lie in corners

-arrows B- of ear on O-type clip. |

| – |

Tighten clamp by turning spindle with a torque wrench (do

not cant pliers).

|

Note Note

| Due to the hard material of the protective boot (compared to

rubber) and the necessity of using a stainless steel clamp, it

is only possible to tension the clamp with clamp tensioner -V.A.G

1682-. |

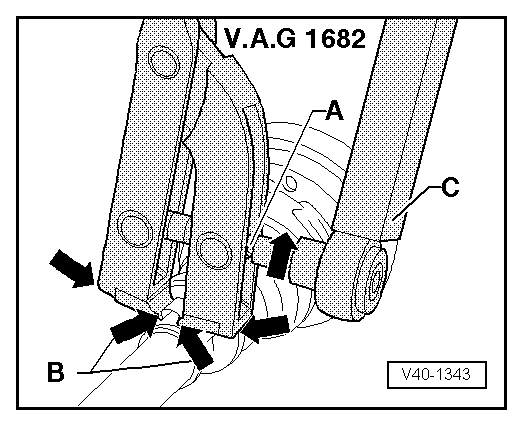

| Use torque wrench -C - with

setting range of 5 ... 50 Nm (e.g. torque -V.A.G 1331-). |

| Make sure thread of spindle -A-

on pliers moves freely. Lubricate with MoS2 grease if necessary. |

| If the thread is tight (e.g. due to dirt), the required

clamping force for the clamp will not be attained although the

specified tightening torque is applied. |

|

|

|

| Tightening clamp on small diameter |

|

|

|

Special tools and workshop equipment

required

Torque wrench -V.A.G 1332-

...

Special tools and workshop equipment

required

Socket, 24 mm -T10361A-

...

Other materials:

Wear in middle of tyre

This wear pattern is found on the driven wheels of

high-performance vehicles that are frequently driven long

distances at high speeds.

At high speeds, centrifugal forces cause the tyre diameter

to increase more in the middle of the tread ...

Dealing with problems with Midtronics -MCR340V- battery tester

Under certain circumstances, the display may show errors or

messages according to status.

The most frequent display messages are listed below,

together with suggested solutions.

Note

For messages not liste ...

Paintwork system for plastic components

Issue 03.2010

This universal system allows simple and reliable painting of

all external plastic components in standard applications.

(Synthetic types: PP, EPDM, ABS, PC, PPO, PBTP, UP-GF, PA, PVC,

R-TPU, PUR). This technical data sheet i ...

© 2016-2024 Copyright www.vwgolf.org

Note

Note Note

Note Removing and installing drive shaft

Removing and installing drive shaft Loosening and tightening threaded connections of drive shaft

Loosening and tightening threaded connections of drive shaft