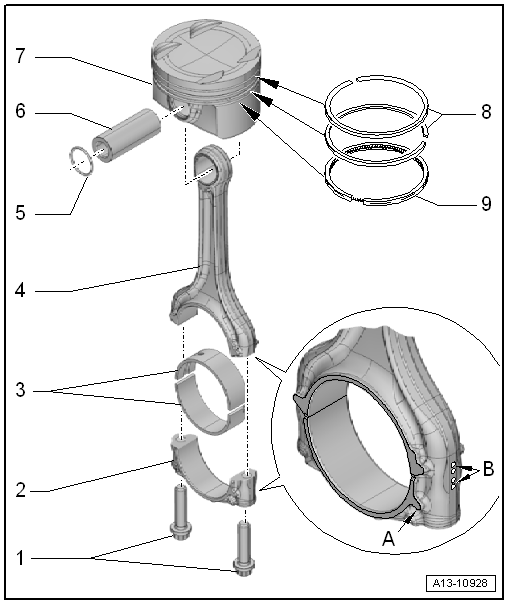

Volkswagen Golf Service & Repair Manual: Assembly overview - pistons and conrods

| Oil threads and contact surface |

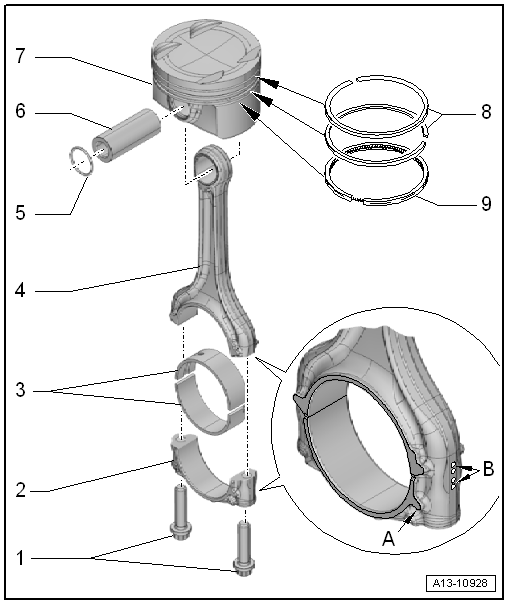

| The conrod bearing cap only fits in one position and only on the

appropriate conrod due to the breaking procedure (cracking) separating

the cap from the conrod. |

| Mark allocation to cylinder and conrod in colour

-B-. |

| Installation position: Lug -A- on

conrod bearing cap faces towards pulley end |

| Installation position → Fig. |

| Renew worn bearing shells |

| With industrially cracked conrod bearing cap |

| Mark allocation to cylinder and conrod bearing cap in colour

-B-. |

| Measuring radial clearance

→ Chapter |

| Separate new conrod → Fig.. |

| Installation position: Lug -A- on

conrod bearing cap faces towards pulley end |

| Removing and installing

→ Chapter „Removing and installing pistons“ |

| Mark installation position and cylinder number

→ Fig.. |

| Removing and installing

→ Chapter |

| Checking piston and cylinder bore

→ Chapter |

| Measuring ring gap

→ Fig. |

| Measuring ring-to-groove clearance

→ Fig. |

| Use commercially available piston ring pliers to remove and install. |

| Installation position: marking “TOP” or side with lettering towards

piston crown |

| Measuring ring gap

→ Fig. |

| Measuring ring-to-groove clearance

→ Fig. |

| Use piston ring pliers to remove and install. |

| Installation position: marking “TOP” or side with lettering towards

piston crown |

| Offset gap 120° relative to lower compression ring |

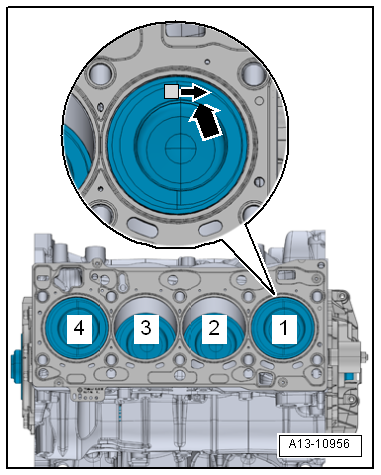

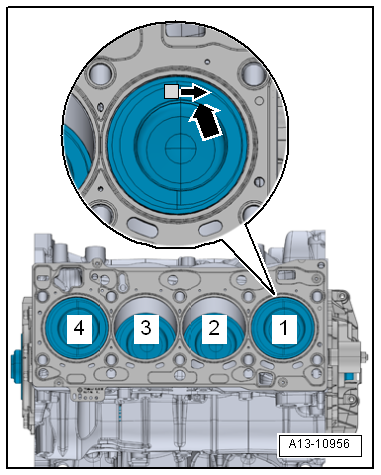

| Installation position and allocation of piston to cylinder |

| Arrow on piston crown points to pulley end

-arrow-. |

|

|

|

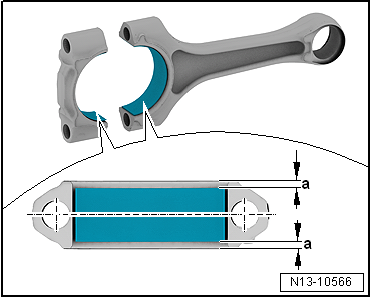

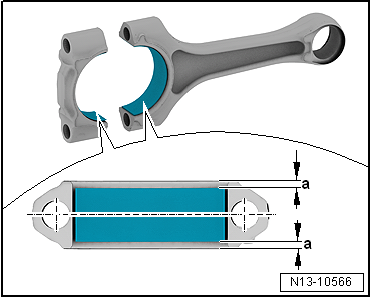

| Bearing shells - installation position |

| – |

Centre bearing shells on conrod and on conrod bearing cap. |

|

|

|

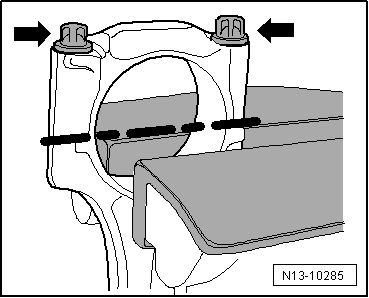

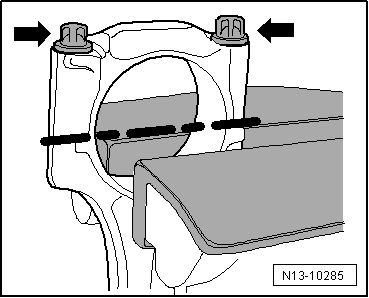

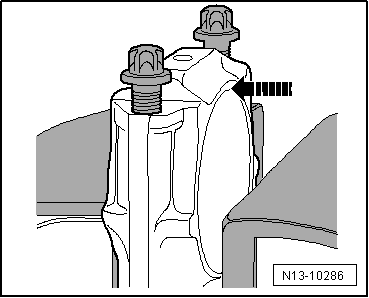

| On new conrods it is possible that the breaking point is not

fully separated. When the conrod bearing cap cannot be removed

by hand, proceed as follows: |

| – |

To avoid damage, gently clamp conrod in a vice with

protection jaws, as shown in illustration. |

| Clamp conrod below dashed line. |

| – |

Unscrew bolts -arrows- around 5

turns. |

|

|

|

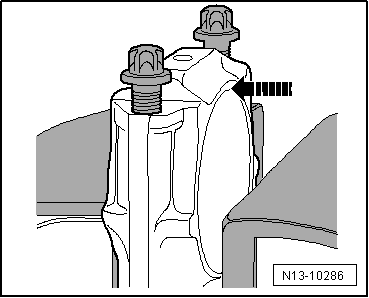

| – |

Using a plastic hammer, carefully knock against conrod

bearing cap -arrow- until it is

loose. |

|

|

|

Special tools and workshop equipment

required

Drift -VW 222 A-

Piston ring ...

© 2016-2026 Copyright www.vwgolf.org

Removing and installing pistons

Removing and installing pistons