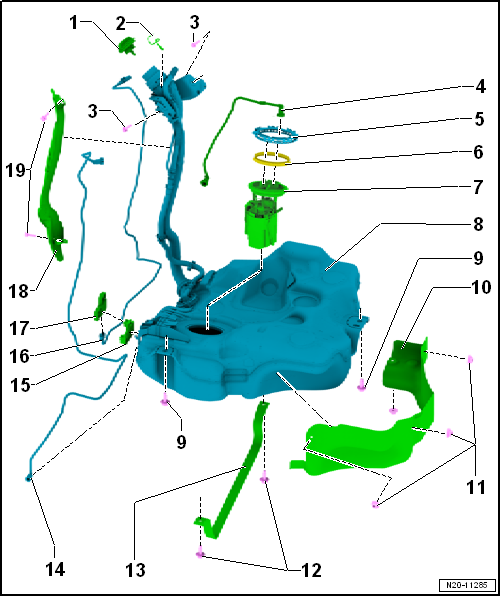

Volkswagen Golf Service & Repair Manual: Assembly overview - fuel tank, vehicles with fuel tank leak detection

| 1 - | Cap |

| Screw in until engages audibly |

| Secured to tank flap unit by means of retaining strap. |

| 2 - | Earth connection |

| For fuel filler neck |

| 3 - | Bolt |

| Renew after removing |

| 8 Nm + 90° |

| 4 - | Fuel supply line |

| Clipped onto fuel tank |

| Do not kink |

| To pull off, press release button on connection. |

| Plug-in connectors must engage »audibly« when joined. |

| Ensure plug-in connector is secured properly by pulling it. |

| Disconnect plug-in connectors → Chapter |

| 5 - | Locking ring |

| 110 Nm |

| 6 - | Seal |

| Renew. |

| Install dry. |

| 7 - | Fuel delivery unit |

| Assembly overview → Chapter. |

| Removing and installing → Chapter. |

| With fuel gauge sender -G-. |

| Removing and installing fuel gauge sender -G- → Chapter. |

| With fuel system pressurisation pump -G6-. |

| Checking fuel system pressurisation pump -G6- → Chapter. |

| 8 - | Fuel tank |

| Removing and installing → Chapter. |

| 9 - | Bolt |

| Renew after removing |

| 20 Nm + 90° |

| 10 - | Heat shield |

| For fuel tank |

| 11 - | Panel nut |

| For heat shield. |

| 12 - | Bolt |

| Renew after removing |

| 20 Nm + 90° |

| 13 - | Securing strap |

| Ensure proper seating. |

| Mark direction of travel when removing. |

| 14 - | Breather line |

| To activated charcoal filter solenoid valve 1 -N80- |

| 15 - | Bracket |

| For control unit for fuel tank leak detection -J909-. |

| 16 - | Connecting cable |

| For control unit for fuel tank leak detection -J909-. |

| 17 - | Control unit for fuel tank leak detection -J909- |

| 18 - | Protective plate |

| 19 - | Rivets |

| For securing protective plate |

Assembly overview - fuel tank, vehicles with front-wheel drive and torsion

beam rear suspension

Assembly overview - fuel tank, vehicles with front-wheel drive and torsion

beam rear suspension

1 -

Cap

Screw in until engages audibly

Secured to tank flap unit by means of retaining strap.

2 -

Earth connecti ...

Assembly overview - fuel tank, vehicles with four-wheel drive

Assembly overview - fuel tank, vehicles with four-wheel drive

1 -

Breather line

To activated charcoal filter

Do not kink

Clipped onto fuel tank

To pull off, press rele ...

Other materials:

Classification of extraction and charging devices in groups

Group 3:

Portable extraction and charging devices linking the air

conditioning system to a fixed compressed gas container.

The fixed compressed gas container is charged with

refrigerant or refrigerant/oil mixture. The po ...

Removing and installing flywheel

Special tools and workshop equipment

required

Counterhold -3067-

Removing

Gearbox removed

...

Removing and installing control unit and hydraulic unit, LHD vehicles,

diesel engine

Special tools and workshop equipment required

Torque wrench -V.A.G 1331-

Torque wrench -V.A.G 1410-

Brake pedal depressor -V.A.G 1869/2-

Sealing plugs, assemb ...