Volkswagen Golf Service & Repair Manual: 2-pack surfacer

| 2-pack surfacer -LLS MAX 202 M2-, medium grey |

| The 2-pack surfacer -LLS MAX 202 M2-, medium grey, is a

high-grade two-pack HS sanding surfacer. The raw material basis

is acrylic resins. |

| Constant atomisation pressure. |

| Finest aerosol dispersion. |

| Optimum flow, reliable application. |

| Outstanding vertical stability. |

| Excellent sanding properties. |

| Field of application: Clever Repair |

| First-class painting results. |

Note Note

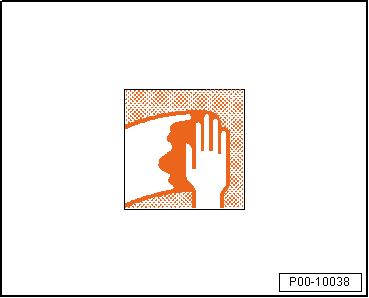

| Protective garments and equipment in accordance with work

safety regulations must be worn. |

| Sheet steel, galvanised/zinc-plated sheet steel or soft

aluminium, cleaned, sanded and coated with 2-pack wash primer

-LHV 043 000 A2- or 1-pack wash primer -LVM 044 007 A2-/-LVM 044

171 A2-. |

| Finely sanded, thoroughly cleaned original factory primer. |

| Lightly sanded factory paint or old paint (except TPAs,

thermoplastic acrylics). |

| Surfaces pre-treated with 2-pack polyester products and then

finely sanded. |

| Cleaned and sanded UP-GF surfaces, free of release agents. |

|

|

|

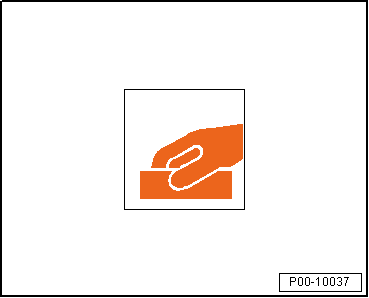

| – |

Thoroughly clean with silicone remover -LVM 020 000 A5- or

slow-drying silicone remover -LVM 020 100 A5-. |

|

|

|

| – |

Lightly sand old or factory paintwork. |

| – |

Completely remove any rust spots and sand feather edges to

old paint. |

|

|

|

| – |

Before recoating, use a suitable cleaning agent to ensure a

clean surface free of residues. |

|

|

|

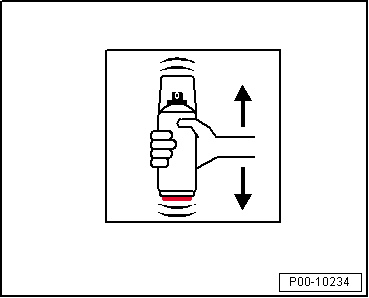

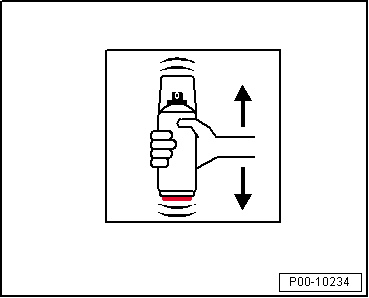

| Activation of 2-pack aerosol can: |

|

|

|

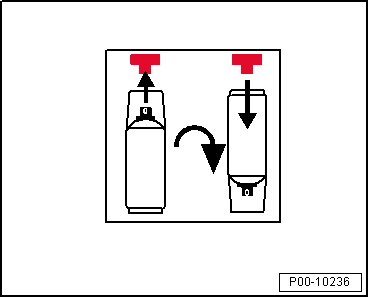

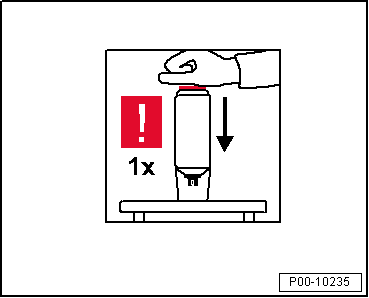

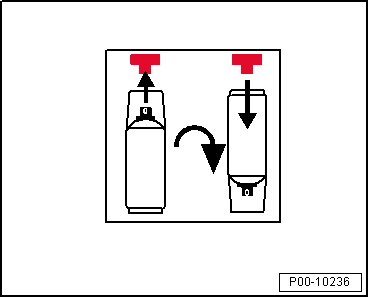

| – |

Remove red push button from cap and place on hardener mixing

valve on bottom of can. |

|

|

|

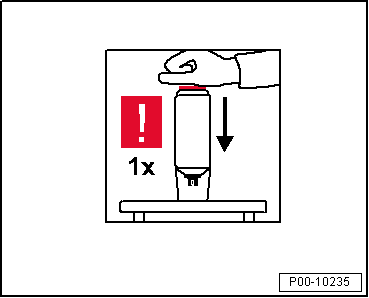

| – |

Press in hardener mixing valve. When pressing down hardener

mixing valve, be sure that the can is inverted. |

|

|

|

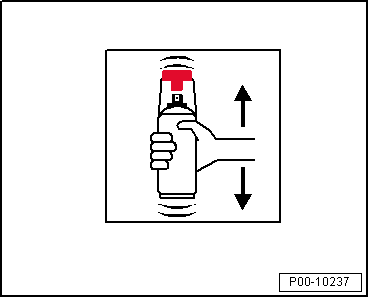

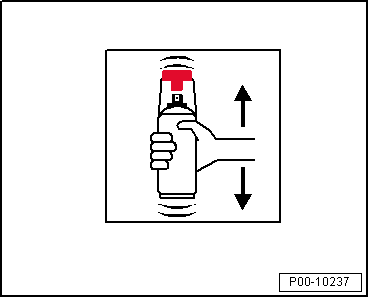

| – |

Vigorously shake can for at least 2 minutes. |

|

|

|

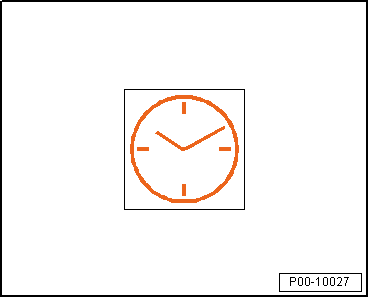

| Application time/pot life: |

|

|

|

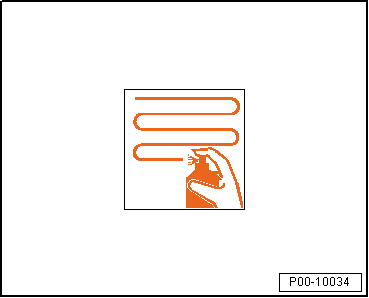

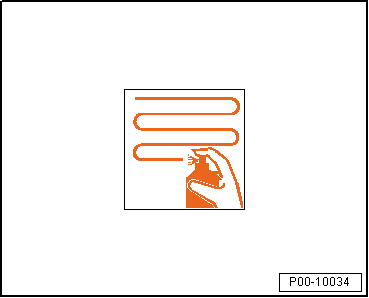

| Method of application: “spray”. |

| – |

Apply in 2-3 full spray coats with 5-10 minutes intermediate

flash-off time between individual coats. |

| – |

Maintain a distance of 20-25 cm. |

| – |

The specified thickness for the dry film is approx. 80 to

120 µm. |

Note Note

| If spray work must be interrupted, ensure that the nozzle is

cleared to avoid clogging by inverting the can and spraying

until the valve is empty. |

|

|

|

| Air drying at ambient temperature of +20 °C: |

| 3 to 4 hours for dry-film thickness of 80-120 µm. |

|

|

|

| Flash-off time with force drying is at least 5-15 minutes. |

| Force drying period at object temperature of +60 °C is 30 to

40 minutes for a film thickness of 80 to 120 µm. |

|

|

|

| Flash-off time with infrared drying is at least

5-10 minutes. |

|

|

|

| For a film thickness 80 to 120 µm, the final flash-off time

with infrared drying is 10 minutes (short wave) or 15 minutes

(medium wave). |

|

|

|

| – |

Dry sand using orbital sander with P400 to P500-grain

sandpaper and dust collector. |

|

|

|

| – |

Wet sand with P800 to P1000-grain sandpaper. |

|

|

|

| Waterborne base coat and 2-pack HS clear coat |

Note Note

| Any substrate defects can be treated with 2-pack polyester

filler. |

| After drying and intermediate sanding, treated spots can be

isolated again using 2-pack epoxy primer surfacer -LLS MAX 220

M1/M2- or a 2-pack HS Premium surfacer. |

| When isolating (even on problem substrates), the best

results are achieved after 2 to 3 spray coats (medium film

thickness of 80-120 μm), after either air drying overnight,

force drying or infrared drying. With problem substrates,

careful pretreatment is imperative, and the surfacer must be

applied to the entire surface. |

| For isolating thermoplastic paint, 2-pack HS Vario surfacer

-LGF 786 004 A4-, grey, is recommended. |

Caution

Caution

| Protective garments and equipment in accordance with

work safety regulations must be worn. |

| Observe safety information sheets as well as

warnings on the label of the spray can. |

| Shake again briefly before spraying each coat. |

| After fully emptying the spray can, dispose of as

recycling material |

|

WARNING

WARNING

| Coating materials ready for application which

contain isocyanate may cause irritation to mucous

membranes - especially the respiratory organs - and

cause hypersensitive reactions. |

| Sensitisation may occur if vapours or spray mist are

inhaled. |

| Carefully observe all rules for working with coating

materials containing solvents when working with coating

materials containing isocyanate. Particular care must be

taken to prevent inhalation of spray mist and vapour. |

| Persons suffering from allergies, asthma or other

respiratory problems should not work with coating

products containing isocyanate. |

|

|

|

|

| VOC content:

2004/42/IIB(e)(840)690 |

The EU limit value for this

product (product category IIB.b) in ready-to-spray form is max. 840 g/l

of volatile organic compounds. The VOC content of this product in

ready-to-spray form is max. 690 g/l. |

| The guaranteed shelf life is 36 months from date of

production. May be used until the date stated on the label at

latest if stored in sealed original containers at +20 °C. |

|

|

|

1-pack fill clean spray can -LLS MAX 112-, 400 ml for

water-based mixing paint “Aquaplus premium system”

Issue 05.2014

...

Designation:

2-pack clear coat -LLS MAX 210-

Issued 12.2010

Product description

...

Other materials:

Removing and installing brake servo, right-hand drive vehicle

Special tools and workshop equipment

required

Torque wrench -V.A.G 1331-

Torque wrench -V.A.G 1410-

...

Assembly overview - dash panel central tube

Note

If electrical wires are disconnected or removed and installed, it

is useful to make corresponding drawings or photos. This guarantees that

everything is re-installed in its original position.

1 -

Securing bracket

Welded to body ...

Refrigerant circuit seals

Renew seals.

Moisten seals with refrigerant oil before installing.

Ensure proper seating of seals on the pipe or in the groove.

Work in a completely clean environment (the smallest

particles ...

© 2016-2026 Copyright www.vwgolf.org

Note

Note Note

Note Note

Note 1-pack fill clean spray can -LLS MAX 112-, Aqua Premium system

1-pack fill clean spray can -LLS MAX 112-, Aqua Premium system 2-pack clear coat

2-pack clear coat

Caution

Caution WARNING

WARNING